Clear Self Seal Craft Bags: Secure & Versatile Packaging

Introduction to Advanced Self-Sealing Packaging Solutions

In modern packaging, the demand for efficiency, product integrity, and aesthetic appeal has driven significant innovation. Among these advancements, self seal craft bags have emerged as a versatile and indispensable solution across numerous industries. These bags offer unparalleled convenience and protection, simplifying packaging processes while enhancing product presentation. Engineered for diverse applications, from delicate artisan goods to perishable food items, their inherent design allows for quick, secure closure without the need for additional sealing equipment. This document provides a comprehensive overview of their technical specifications, manufacturing intricacies, application versatility, and strategic advantages, tailored for B2B decision-makers and technical professionals seeking optimal packaging solutions.

Our focus extends to the underlying material science, production methodologies, and the tangible benefits these packaging solutions deliver in real-world scenarios, ensuring that our partners gain a deep understanding of their value proposition. The discussion will also cover critical aspects such as compliance with industry standards, customization potential, and a comparative analysis to underscore their competitive edge.

Industry Trends and Market Dynamics for Self-Sealing Bags

The packaging industry is currently experiencing a transformative period, driven by evolving consumer expectations, stringent regulatory requirements, and a heightened focus on sustainability. For self-sealing bags, several key trends are shaping market dynamics:

- Sustainability Mandates: There's a growing demand for eco-friendly packaging materials. This includes the development of biodegradable, compostable, and recyclable films for self seal craft bags, aligning with global efforts to reduce plastic waste. Manufacturers are increasingly investing in plant-based polymers and post-consumer recycled (PCR) content to meet these demands.

- E-commerce Boom: The exponential growth of online retail necessitates packaging solutions that are durable, protective, and easy to open. Clear plastic self sealing bags are ideal for e-commerce, offering secure transit and a professional unboxing experience for various goods, from apparel to small electronics and craft supplies.

- Smart Packaging Integration: Emerging technologies like RFID tags, QR codes, and temperature sensors are being integrated into packaging. While not universal for all self-sealing bag types, this trend points towards future innovations in traceability, supply chain management, and consumer engagement.

- Enhanced Barrier Properties: For sensitive products, particularly in the food and pharmaceutical sectors, advanced barrier films are critical. Innovations in multi-layer co-extrusion technologies are improving oxygen and moisture vapor transmission rates (OTR and MVTR), significantly extending product shelf life. This is especially vital for self sealing bags for food applications.

- Customization and Branding: Brands are increasingly seeking bespoke packaging solutions that reflect their identity. This includes custom sizes, specialized printing techniques, and unique closure mechanisms, transforming functional packaging into a powerful marketing tool, particularly for craft designer self sealing bags.

These trends collectively underscore the dynamic evolution of the self-sealing bag market, positioning it as a critical area for ongoing innovation and strategic investment.

Manufacturing Process of Self Seal Craft Bags

The production of high-quality self seal craft bags involves a sophisticated multi-stage manufacturing process, ensuring material integrity, precise dimensions, and reliable sealing mechanisms. This process integrates advanced polymer science with precision engineering.

Process Flow Schematic:

- Material Selection & Preparation:

- Primary materials: Low-Density Polyethylene (LDPE), High-Density Polyethylene (HDPE), Polypropylene (PP), or specialized co-extruded films (e.g., BOPP/CPP, PET/PE). For enhanced barrier properties, materials like EVOH or metallized films are incorporated. Materials are selected based on desired transparency, tensile strength, tear resistance, and barrier performance.

- Additives: UV stabilizers, anti-static agents, slip agents, and masterbatches for color are blended into the polymer resins.

- Film Extrusion (Casting/Blown Film):

- Resins are fed into an extruder, where they are melted and forced through a die.

- For blown film, the molten polymer forms a tube that is inflated with air, then cooled and flattened into a continuous film. For cast film, the polymer is extruded onto a chilled roll.

- Multi-layer co-extrusion technology is utilized for films requiring specific barrier or structural properties (e.g., an outer layer for printability, a middle layer for strength, and an inner layer for heat sealing).

- Printing (Flexographic/Gravure):

- If custom branding or instructions are required, the film is fed into high-speed printing presses. Flexographic printing is common for its versatility and cost-effectiveness, while gravure printing offers superior image quality for intricate designs.

- Inks used are typically food-grade and resistant to abrasion and fading.

- Lamination (Optional for Multi-Layer Films):

- Different film layers (e.g., printed film, barrier film, sealing film) are bonded together using adhesives under heat and pressure to create composite materials with enhanced properties.

- Bag Converting & Sealing Mechanism Integration:

- The continuous film is fed into a bag-making machine.

- Side and bottom seals are formed using precision heat-sealing bars.

- The self-sealing adhesive strip (typically acrylic or rubber-based) is applied to the lip of the bag. This strip is protected by a release liner for activation by the end-user.

- The film is then cut to the desired bag length.

- Quality Control & Testing:

- Each batch undergoes rigorous testing. Standards include:

- ASTM D882: Tensile Properties of Thin Plastic Sheeting.

- ASTM D1922: Tear Propagation Resistance (Elmendorf Tear).

- ASTM F88/F88M: Seal Strength of Flexible Barrier Materials.

- ISO 2233: Packaging - Complete, filled transport packages and unit loads - Conditioning for testing.

- FDA Compliance: For food contact materials, materials must comply with 21 CFR 177 regulations.

- EN 13432: Requirements for packaging recoverable through composting and biodegradation (for eco-friendly variants).

- Visual inspection for defects, dimensional accuracy checks, and adhesive peel strength tests are routinely performed.

- Each batch undergoes rigorous testing. Standards include:

- Packaging & Dispatch: Finished bags are counted, bundled, and packaged for shipment to clients.

This meticulous process ensures that each self seal craft bag meets stringent quality and performance criteria, offering an optimal service life typically ranging from 12 to 24 months under standard storage conditions, varying based on material composition and environmental factors. Target industries benefiting from this robust manufacturing include e-commerce, retail, crafts & hobbies, food & beverage, and pharmaceutical secondary packaging.

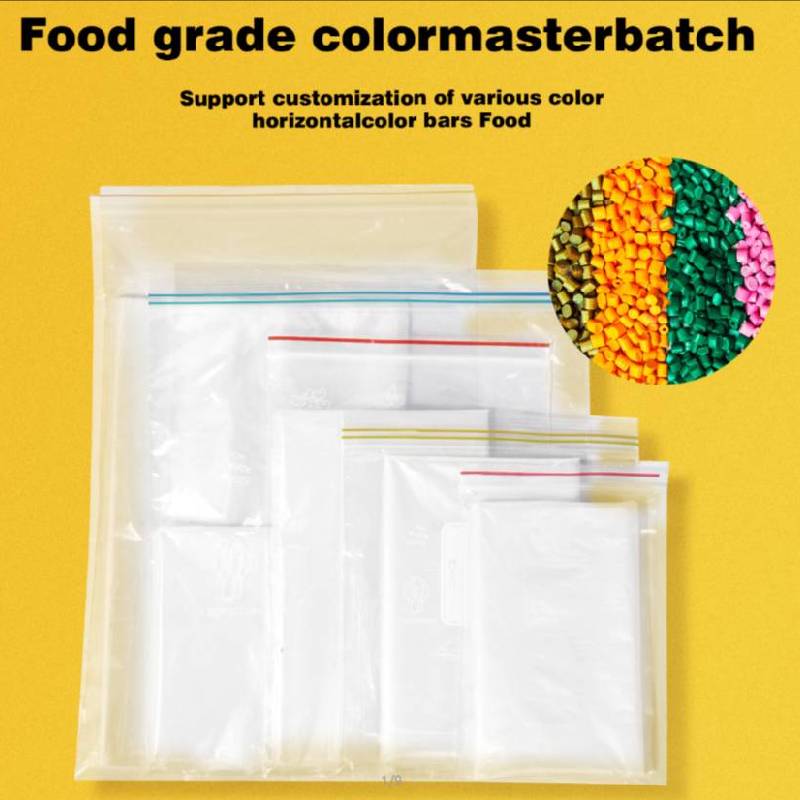

Figure 1: High-precision manufacturing of self-sealing bags.

Technical Specifications and Performance Parameters

Understanding the technical specifications of self seal craft bags is crucial for selecting the appropriate packaging solution. Key parameters dictate performance, protective capabilities, and suitability for various applications.

Typical Product Specification Table:

| Parameter | Value/Range | Unit | Test Standard |

|---|---|---|---|

| Material Composition | LDPE, HDPE, BOPP, PET/PE Laminate (Customizable) | N/A | N/A |

| Film Thickness | 25 - 100 (Customizable) | Microns (µm) | ASTM D6988 |

| Tensile Strength (MD/TD) | 15-30 / 12-25 | MPa | ASTM D882 |

| Elmendorf Tear Strength | 150-400 | Grams | ASTM D1922 |

| Seal Strength (Adhesive) | 2.5 - 5.0 | N/15mm | ASTM F88/F88M |

| Oxygen Transmission Rate (OTR) | 50-500 (dependent on material) | cc/(m²·24hr) | ASTM D3985 |

| Water Vapor Transmission Rate (WVTR) | 5-50 (dependent on material) | g/(m²·24hr) | ASTM E96 |

| Transparency | > 90% (for clear self sealing bags) | % | ASTM D1003 |

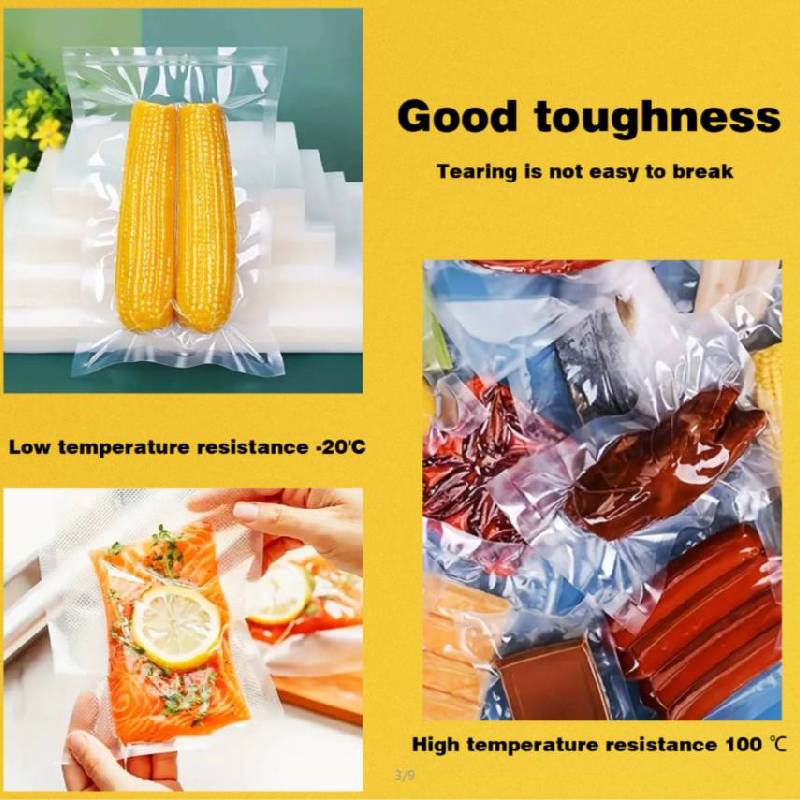

| Operating Temperature Range | -20 to +80 | °C | N/A |

These parameters are critical in determining the suitability of the bag for specific applications, such as protecting moisture-sensitive electronics, preserving freshness in self sealing bags for food, or showcasing delicate craft designer self sealing bags with optimal clarity and durability. Our engineering team can provide detailed data sheets for specific material grades and customized solutions.

Versatile Application Scenarios

The adaptability of self seal craft bags makes them an ideal packaging solution across a multitude of sectors, addressing diverse protection, presentation, and logistical needs.

- Crafts and Hobbies: For artisans and craft suppliers, these bags provide excellent protection for small components like beads, sequins, fabric swatches, or delicate handmade items. The clear visibility offered by clear plastic self sealing bags allows customers to view contents without opening, preserving product integrity. They are particularly favored for their ease of use by independent craft designer self sealing bags vendors.

- E-commerce and Retail: Online retailers leverage these bags for packaging clothing, accessories, small electronics, and general merchandise. The self-sealing mechanism significantly speeds up packing operations, and the durable film protects against dust, moisture, and minor abrasions during transit, contributing to a positive unboxing experience.

- Food and Beverage: Specialized food-grade self sealing bags for food are used for packaging baked goods, candies, snacks, spices, and dried fruits. With appropriate barrier properties (e.g., specific OTR/WVTR for moisture and oxygen), they extend shelf life, maintain freshness, and prevent contamination. Compliance with FDA regulations (21 CFR Part 177) is paramount in this sector.

- Stationery and Office Supplies: Packaging for pens, paper clips, notepads, and other office accessories benefits from the organized presentation and protection provided by clear, reclosable bags.

- Industrial and Component Packaging: In manufacturing, small parts, fasteners, electronic components, or spare parts are often stored and transported in clear self sealing bags, ensuring cleanliness, easy identification, and protection from environmental elements.

Figure 2: Versatile application of self-sealing bags across industries.

These scenarios highlight the intrinsic value of self-sealing bags in streamlining operations and safeguarding product quality across diverse commercial ecosystems.

Technical Advantages and Performance Enhancements

The widespread adoption of self seal craft bags is attributable to a range of technical advantages that directly translate into operational efficiencies and enhanced product value for businesses.

- Superior Product Protection: Engineered from high-quality polymers, these bags offer robust protection against external contaminants such as dust, dirt, and moisture. For specialized applications, multi-layer films provide enhanced barrier properties against oxygen and water vapor, critical for preserving the freshness and integrity of perishable goods, particularly self sealing bags for food.

- Efficiency in Packaging Operations: The pre-applied adhesive strip significantly reduces packaging time and labor costs. Unlike heat-sealable bags that require specialized machinery and cooling periods, these self-sealing solutions can be sealed manually, accelerating throughput, especially for high-volume operations or small businesses. This ease of use is a key advantage for craft designer self sealing bags.

- Enhanced Product Presentation: The high clarity of clear plastic self sealing bags allows for optimal product visibility, showcasing items attractively. This transparency is vital in retail environments or for handmade products where visual appeal influences purchase decisions. Customizable printing options further enhance branding and marketing efforts.

- Versatility and Adaptability: Available in a wide array of sizes, materials, and thicknesses, these bags can be tailored to fit virtually any product. From delicate jewelry to bulky textiles, the customizable nature ensures an ideal fit and appropriate level of protection.

- Cost-Effectiveness: While initial material costs might vary, the long-term savings from reduced labor, minimized product damage during transit, and elimination of additional sealing equipment often make clear self sealing bags a more economical choice in the overall supply chain.

These technical advantages underscore why self-sealing bags are a preferred packaging choice for businesses prioritizing both operational efficiency and superior product care.

Vendor Comparison and Selection Criteria

Choosing the right supplier for self seal craft bags is a critical decision that impacts product quality, supply chain reliability, and overall cost-efficiency. A comparative approach, based on verifiable parameters, is essential.

Vendor Comparison Table (Illustrative):

| Feature/Criteria | Our Company | Competitor A (Premium) | Competitor B (Economy) |

|---|---|---|---|

| Material Quality (Film) | Virgin FDA-grade PE/PP/BOPP, PCR options | Virgin FDA-grade PE/PP | Recycled PE (non-food contact) |

| Adhesive Type & Durability | High-tack, permanent acrylic, 12-month shelf life | Strong acrylic, 9-month shelf life | Rubber-based, 6-month shelf life |

| Customization Options | Full-color printing, custom sizes, anti-static, vent holes, hang tabs | Basic printing, limited sizes | No printing, standard sizes only |

| Certifications & Compliance | ISO 9001, FDA (for food contact), RoHS | ISO 9001 | None specified |

| Lead Time (Standard Orders) | 7-14 business days | 10-20 business days | 14-25 business days |

| Minimum Order Quantity (MOQ) | Flexible, starting from 5,000 units | 10,000 units | 20,000 units |

| Customer Support | Dedicated account manager, 24/7 online support | Email support during business hours | Online FAQ only |

This comparison highlights the importance of evaluating suppliers not just on price, but on a holistic set of criteria including material quality, technical capabilities, service level, and adherence to industry standards for clear plastic self sealing bags. Our commitment to ISO 9001 quality management ensures consistent product excellence and reliability, backed by years of experience in the flexible packaging industry.

Customized Solutions for Unique Packaging Needs

Recognizing that generic packaging rarely fully addresses specific product and brand requirements, we offer extensive customized solutions for self seal craft bags. Our engineering team collaborates closely with clients to develop bespoke packaging that aligns perfectly with their operational and marketing objectives.

- Material Tailoring: From various polyethylene densities (LDPE, HDPE) to polypropylene (BOPP, CPP), and advanced co-extruded films with barrier properties (e.g., EVOH for oxygen barrier, metallized films for UV protection), we can engineer the optimal material blend for specific product needs, including specialized self sealing bags for food and sensitive electronics.

- Dimension and Gauge Precision: Bags can be manufactured to exact dimensions (length, width, lip size) and film thicknesses (gauge) to perfectly fit products, minimizing material waste and maximizing protection. This is crucial for optimizing packaging efficiency and reducing shipping volume.

- Printing and Branding: High-definition flexographic and gravure printing allows for intricate graphics, logos, product information, and barcodes. We offer up to 10-color printing, ensuring brand consistency and visual appeal for craft designer self sealing bags and retail products.

-

Feature Integration: Customizable features include:

- Ventilation holes (for fresh produce or to release trapped air).

- Hang tabs (for retail display).

- Perforations (for easy tearing or multiple compartments).

- Reinforced headers (for heavy items).

- Anti-static properties (for electronics).

- Tamper-evident seals (for security).

- Adhesive Specificity: Options for adhesive strength (permanent vs. reclosable) and type (silicone vs. acrylic) are available to match usage requirements.

Our comprehensive customization capabilities ensure that every clear self sealing bags order is optimized for performance, aesthetics, and cost-efficiency, providing a true competitive advantage.

Application Case Studies

Real-world applications demonstrate the tangible benefits and successful integration of self-sealing bag solutions into diverse operational frameworks.

Case Study 1: E-commerce Fulfillment for Artisan Jewelry

A rapidly growing online retailer specializing in handmade artisan jewelry faced challenges with packaging efficiency and product presentation. Their previous method involved manual bagging and separate sealing with tape, leading to slow fulfillment times and inconsistent aesthetics.

- Solution Implemented: We provided custom-sized, clear plastic self sealing bags made from high-clarity BOPP film, printed with the company's delicate logo and care instructions. The bags featured an anti-static property to protect sensitive metal components from static discharge.

-

Results Achieved:

- Reduced packaging time by 30%, increasing daily order fulfillment capacity.

- Enhanced brand perception due to consistent, professional packaging.

- Minimized product damage during shipping, leading to a 15% reduction in customer returns related to packaging issues.

Case Study 2: Extending Shelf Life for Organic Bakery Products

An organic bakery sought to expand its distribution to larger retail chains, requiring extended shelf life for their artisan bread and pastries without compromising product freshness or chemical preservatives.

- Solution Implemented: We engineered specialized multi-layer self sealing bags for food featuring an EVOH barrier layer and an internal anti-fog coating. These bags were designed to maintain specific internal humidity levels and drastically reduce oxygen transmission.

-

Results Achieved:

- Increased product shelf life from 3 days to 7 days, opening new retail market opportunities.

- Maintained product freshness, taste, and texture, leading to positive consumer feedback.

- Reduced food waste by 20% across their supply chain.

Figure 3: Customized self-sealing bags for varied applications.

These case studies underscore our capability to deliver measurable improvements in operational efficiency, product integrity, and market reach through expertly engineered clear self sealing bags.

Frequently Asked Questions (FAQ)

- Q: Are your self-sealing bags recyclable?

- A: Many of our standard polyethylene (PE) bags are recyclable through specific recycling streams (e.g., store drop-off programs for plastic films). We also offer options made from post-consumer recycled (PCR) content and fully compostable materials (certified to EN 13432) to meet sustainability goals. Please inquire about specific product certifications for your particular needs.

- Q: What is the typical lead time for custom orders?

- A: Standard lead time for custom printed or sized self-sealing bags is typically 10-14 business days after final artwork approval and material confirmation. Rush orders can be accommodated depending on production schedule and material availability, subject to additional fees. We maintain a flexible fulfillment model to support varied client requirements.

- Q: Do you provide samples before a large order?

- A: Yes, we highly recommend providing samples. Generic samples of our standard clear self-sealing bags are usually free, while custom-printed samples may incur a nominal tooling fee, which is often credited against the final production order. This ensures client satisfaction with material, size, and print quality before full production.

- Q: What are your warranty commitments for your products?

- A: Our self-sealing packaging solutions are manufactured under strict ISO 9001 quality standards and come with a warranty against manufacturing defects for 12 months from the date of purchase, provided they are stored under recommended conditions. This warranty covers material integrity, seal strength, and adhesive performance. We stand behind the quality and reliability of our flexible packaging solutions.

- Q: How do you handle after-sales support and technical inquiries?

- A: We offer comprehensive after-sales support, including a dedicated account manager for ongoing communication, and technical support specialists available to address any performance, application, or material-related inquiries. Our team is accessible via phone, email, and a dedicated client portal during business hours, ensuring prompt and expert assistance for all our packaging products.

Conclusion: Strategic Packaging for Future Success

The selection of appropriate packaging is no longer merely a logistical consideration; it is a strategic decision that profoundly impacts brand perception, operational efficiency, and ultimately, market success. These versatile self-sealing packaging solutions represent a pinnacle of flexible packaging innovation, offering a harmonious blend of practical utility, robust protection, and aesthetic versatility. By leveraging advanced materials and precision manufacturing processes, these bags provide critical solutions for industries ranging from intricate artisan crafts to demanding food packaging.

Our commitment to quality, customization, and adherence to international standards ensures that our partners receive packaging solutions that not only meet but exceed their expectations. As industry trends continue to emphasize sustainability, efficiency, and enhanced user experience, investing in high-quality self-sealing bags positions businesses for continued growth and competitive advantage. We invite you to explore how our tailored solutions can optimize your packaging strategy and contribute to your long-term success.

-

Premium Poly Mailer Bags - Secure & Lightweight Shipping SolutionsNewsAug.28,2025

-

No-Sew Methods for Making a Drawstring BagNewsAug.22,2025

-

The Problem with Plastic Trash Bags in LandfillsNewsAug.22,2025

-

Biodegradable Alternatives to Shirt BagsNewsAug.22,2025

-

Creative Ways to Reuse Poly Wrap Roll at HomeNewsAug.22,2025

-

Shipping Fragile Items Safely with Bubble MailersNewsAug.22,2025

-

Have the freedom of customizing your custom mailers any way you want! Our dedicated packaging support will help deliver you the mailing experience you need to elevate your shipping experience to the next level! Start making a strong impression on your customers and stand out from your competitors! -

LIYA uses high quality raw materials which directly purchased from large enterprises domestic and overseas such as PetroChina, Sinopec, Sabic, Equate, ExxonMobil, Dow Chemical, Total, and Borouge, ensuring the price advantage and quality of the raw materials. -

LIYA uses high quality raw materials which directly purchased from large enterprises domestic and overseas such as PetroChina, Sinopec, Sabic, Equate, ExxonMobil, Dow Chemical, Total, and Borouge, ensuring the price advantage and quality of the raw materials.