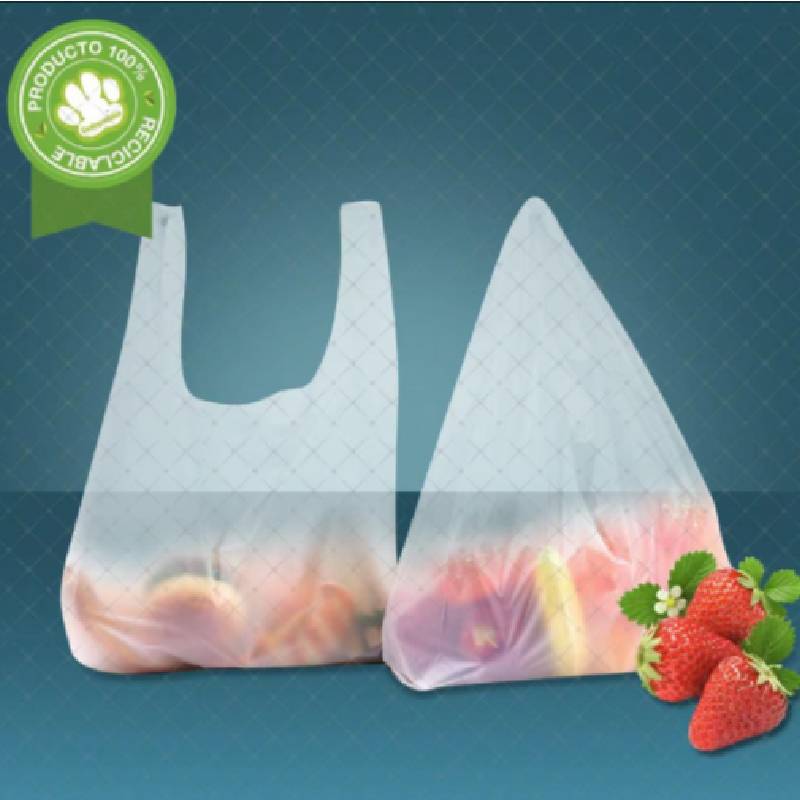

Custom Printed T-Shirt Bags Wholesale - Reusable Options

Understanding T-shirt Bags: A Comprehensive B2B Insight

In the vast landscape of packaging solutions, t shirt bags stand out as an omnipresent and indispensable item in retail, food service, and various commercial sectors. Known for their distinctive handle design resembling a t-shirt, these bags offer unparalleled convenience, cost-effectiveness, and versatility for businesses requiring efficient point-of-sale packaging. This detailed guide delves into the technical specifications, manufacturing processes, industry applications, and strategic considerations for businesses procuring these essential carry solutions, emphasizing durability, sustainability, and customization for the modern market.

The evolution of t shirt bags reflects broader shifts in consumer behavior and environmental consciousness. While traditional high-density polyethylene (HDPE) versions remain prevalent due to their strength and lightweight properties, there's a growing demand for eco-friendlier alternatives, including biodegradable, compostable, and reusable t shirt bags. Understanding the nuances of material composition, tensile strength, and appropriate film thickness is crucial for B2B buyers to ensure optimal performance and compliance with evolving regulatory standards. This article will provide a robust framework for informed decision-making, ensuring that your procurement aligns with both operational needs and corporate responsibility goals.

Industry Trends and Market Dynamics

The market for t shirt bags is currently shaped by several significant trends. Firstly, the global push towards sustainability has accelerated the adoption of materials like HDPE, LDPE, PP, and increasingly, innovative bioplastics such as PLA (Polylactic Acid) and PHA (Polyhydroxyalkanoates), which offer biodegradable or compostable properties. According to a report by Grand View Research, the global plastic bags and sacks market size was valued at USD 28.5 billion in 2022 and is projected to grow, with a notable shift towards sustainable alternatives due to stringent regulations and consumer preference. This underscores the importance for businesses to consider the long-term environmental impact alongside immediate cost benefits.

Secondly, customization and branding play a pivotal role. Businesses are increasingly leveraging custom printed plastic t shirt bags wholesale to enhance brand visibility and customer experience. Advanced flexographic printing technology allows for high-resolution graphics, logos, and promotional messages, transforming a functional item into a powerful marketing tool. The rise of e-commerce and food delivery services has also driven demand for specialized t shirt carry bags designed for robustness and ease of transport, ensuring product integrity from seller to consumer. Furthermore, automation in manufacturing processes is leading to higher efficiency and cost reductions, making bulk procurement more accessible and competitive for businesses of all sizes.

Detailed Manufacturing Process of T-shirt Bags

The production of t shirt bags involves a sophisticated multi-stage process designed to ensure consistency, durability, and cost-effectiveness. The primary raw materials are typically polymer resins such as HDPE (High-Density Polyethylene), recognized for its high strength-to-density ratio and excellent moisture barrier properties, or LDPE (Low-Density Polyethylene), which offers greater flexibility and tear resistance. For eco-friendly variants, biopolymers like PLA or blends with starch are utilized. The manufacturing process typically follows these key steps:

- Film Blowing/Extrusion: Raw resin pellets are melted and extruded through a die to form a continuous tube of plastic film. This film is then inflated by air pressure to a desired diameter and thickness, creating a bubble that is cooled and flattened into a dual-layer sheet.

- Printing (Optional): If custom branding is required, the flattened film undergoes flexographic printing. This method uses flexible relief plates and fast-drying inks to apply designs, logos, and text with high precision and speed. Multiple colors can be applied in a single pass, making custom printed t shirt bags wholesale an efficient branding solution.

- Bag Cutting and Sealing: The printed or unprinted film is then fed into an automated bag-making machine. This machine precisely cuts the film to the desired length and heat-seals the bottom and side seams, forming the basic bag structure. Integrated punching mechanisms create the distinctive t-shirt style handles and ensure consistent dimensions for each bag.

- Perforating and Rolling/Stacking: Finished bags are then perforated (if designed for easy tear-off rolls) or stacked and packed for shipment. Quality control checks are performed at various stages to ensure adherence to specifications such as bag dimensions, film thickness (measured in mils or microns), seal strength, and print quality.

Inspection standards for these products often include ISO 9001 for quality management systems, FDA compliance for food contact applications, and specific ASTM or EN standards for biodegradable and compostable materials (e.g., ASTM D6400 or EN 13432). The typical service life of a single-use t shirt bag is limited to one or a few uses, while reusable t shirt bags are designed for significantly extended lifecycles, often hundreds of uses, impacting their environmental footprint positively. Applicable industries span across retail, supermarkets, food service (take-out and delivery), healthcare, and promotional events, where their versatility and efficiency are highly valued.

Technical Advantages and Performance Metrics

The technical superiority of well-engineered t shirt bags lies in their balanced properties, offering significant advantages for commercial use. Their unique handle design distributes weight effectively, making them comfortable to carry even when heavily loaded, which is a critical feature for grocery and retail applications. Key performance metrics include tensile strength, tear resistance, and puncture resistance. For instance, a typical HDPE t shirt bag often features a film thickness ranging from 0.5 mil to 1.5 mil, offering a surprisingly high load capacity relative to its weight and material cost. This thinness contributes to source reduction, minimizing raw material consumption.

Furthermore, modern manufacturing techniques ensure uniform film thickness and consistent seal integrity, minimizing bag failures during transit or use. The efficiency of production lines for t shirt bags translates into lower unit costs for bulk buyers, making them an economically viable choice for high-volume operations. Compared to paper bags, plastic t shirt bags offer superior moisture resistance, protecting contents from spills or environmental dampness, crucial for food takeout and delivery. For businesses prioritizing sustainability, options like certified compostable or biodegradable bags provide an eco-friendly alternative without compromising essential functional properties, meeting evolving consumer and regulatory expectations for responsible packaging.

Product Specifications and Data Table

Understanding the specific parameters of t shirt bags is vital for making informed procurement decisions. The table below outlines common specifications and characteristics that B2B buyers should consider, providing a comparative overview of different types and their typical performance metrics. These values can vary based on manufacturer and specific application requirements.

| Parameter | HDPE T-shirt Bag | LDPE T-shirt Bag | Compostable T-shirt Bag (e.g., PLA/Starch) | Reusable PP Non-Woven Bag |

|---|---|---|---|---|

| Material Type | High-Density Polyethylene | Low-Density Polyethylene | Polylactic Acid (PLA), Corn Starch Blends | Polypropylene Non-Woven Fabric |

| Thickness (mil) | 0.5 - 1.5 mil | 1.0 - 2.5 mil | 0.8 - 2.0 mil | 70 - 120 GSM (grams per square meter) |

| Typical Dimensions (WxH+G) | 10x18+5", 1/6 BBL, 1/8 BBL | 12x20+6", 1/6 BBL, 1/8 BBL | 10x18+5", 1/6 BBL (similar to HDPE) | 13x15x8", 16x12x6" (varies widely) |

| Load Capacity (lbs) | Up to 20 lbs (9 kg) | Up to 25 lbs (11 kg) | Up to 15 lbs (7 kg) | Up to 35 lbs (16 kg) |

| Environmental Impact | Recyclable (Code 2), long degradation time | Recyclable (Code 4), long degradation time | Compostable in industrial facilities (ASTM D6400, EN 13432) | Reusable for hundreds of uses, then recyclable |

| Typical Use | Grocery, Retail, General Merchandise | High-end Retail, Heavier Items, Food Takeout | Eco-conscious Retail, Food Service (compost programs) | Premium Retail, Promotional, Long-term use |

Choosing the right type of t shirt bag depends heavily on the intended application, desired load capacity, and sustainability goals. For instance, while HDPE offers excellent value and strength, LDPE provides a softer feel and better print quality for premium branding. Compostable bags represent a significant step towards circular economy principles, aligning with corporate environmental policies. Reusable t shirt bags, often made from non-woven polypropylene, represent the pinnacle of sustainability for businesses able to implement re-use programs or encourage customer adoption.

Customization Options and Strategic Solutions

For businesses, custom printed t shirt bags wholesale are not merely a utility but a powerful branding and marketing asset. Customization allows for businesses to extend their brand identity beyond the storefront and into the hands of their customers, creating mobile advertisements. Options include full-color printing using advanced flexographic techniques, enabling intricate designs, brand logos, contact information, and promotional messages to be vividly displayed. This transforms a simple carry solution into a walking billboard, enhancing brand recall and customer loyalty. The ability to control print quality, color accuracy (Pantone matching), and graphic crispness is critical for maintaining brand consistency.

Beyond visual branding, customization also extends to the physical properties of the t shirt bag. Businesses can specify desired dimensions to accommodate specific product lines, choose film thickness to optimize strength-to-cost ratios, and select material compositions for specific environmental mandates or consumer preferences (e.g., opting for thicker, more durable LDPE bags for high-end boutiques or biodegradable bags for eco-conscious enterprises). Furthermore, bulk purchasing of custom printed plastic t shirt bags wholesale often unlocks significant cost efficiencies, reducing per-unit expenditure and ensuring a consistent supply chain for high-volume operations. Partnering with a manufacturer capable of meeting diverse customization needs ensures that the packaging aligns perfectly with both brand strategy and operational demands.

Application Scenarios and Success Stories

The versatility of t shirt bags makes them suitable for an extensive range of application scenarios across various industries. In the retail sector, they are the ubiquitous choice for supermarkets and convenience stores due to their high load capacity, cost-effectiveness, and ease of dispensing at checkout counters. For example, a major grocery chain successfully transitioned its checkout bags to a slightly thicker, certified reusable t shirt bag variant, which not only reduced single-use plastic consumption by 30% in its pilot program but also enhanced customer perception of their commitment to sustainability, fostering greater loyalty.

In the food service industry, particularly for take-out and delivery, t shirt carry bags are essential for safely transporting meals. Their robust handles and gusseted sides ensure that container111s remain upright, minimizing spills during transit. A regional restaurant chain noted a 15% reduction in customer complaints related to spillage after upgrading to more durable t shirt bags with improved seal integrity. Beyond traditional uses, these bags also find utility in healthcare for patient belongings, in promotional events for distributing marketing materials, and in general merchandise for everyday purchases. Their adaptability and ability to be custom branded make them a strategic choice for businesses looking for both functional and marketing value in their packaging.

Manufacturer Comparison and Choosing the Right Partner

Selecting a reputable manufacturer for t shirt bags is critical for ensuring product quality, supply chain reliability, and competitive pricing. Key factors for B2B buyers to evaluate include a manufacturer's adherence to international quality standards (e.g., ISO 9001:2015 certification for quality management), their capacity for large-volume production, and their flexibility in offering custom printed plastic t shirt bags wholesale. Experience in the industry, evidenced by years of service and a robust portfolio of client partnerships, indicates stability and expertise. For example, a manufacturer with over a decade of specialization in packaging solutions demonstrates a deep understanding of market needs and technical requirements.

Furthermore, assessing a manufacturer's commitment to sustainability is increasingly important. This includes their ability to produce reusable t shirt bags, biodegradable options, or those made from recycled content, alongside proper certifications like FDA compliance for food-grade materials or ASTM/EN standards for compostability. A transparent supply chain, clear communication regarding lead times, and comprehensive customer support are equally vital for a seamless procurement process. Prioritizing manufacturers who offer extensive customization options, competitive bulk pricing, and a proven track record of on-time delivery will significantly benefit a business's operational efficiency and brand reputation.

Frequently Asked Questions (FAQ)

Q1: What is the typical lead time for custom printed t shirt bags wholesale orders?

A1: Lead times for custom printed t shirt bags wholesale typically range from 4-8 weeks, depending on the complexity of the design, order volume, and current production schedule. Non-printed or standard stock orders usually have shorter lead times, often 1-2 weeks. We recommend confirming specifics during the quotation process.

Q2: Are your t shirt bags compliant with food safety regulations?

A2: Yes, our food-grade t shirt bags are manufactured from virgin resins and comply with relevant food contact regulations, such as FDA standards in the United States and EU food contact regulations. Certificates of conformity can be provided upon request for specific batches.

Q3: What are the minimum order quantities (MOQ) for custom bags?

A3: MOQs for custom printed plastic t shirt bags wholesale vary based on material, size, and print complexity, typically starting from 25,000 to 50,000 bags. This ensures cost-effectiveness for both the client and the manufacturer through efficient production runs. Please contact our sales team for precise MOQ details tailored to your specific needs.

Q4: Do you offer samples of your reusable t shirt bags?

A4: Yes, we can provide samples of our reusable t shirt bags and other bag types for quality evaluation and material assessment prior to placing a bulk order. Sample requests can be made through our website or by contacting our customer support team.

Q5: What is your warranty and return policy for bulk orders of t shirt bags?

A5: We stand behind the quality of our t shirt bags. Our products come with a standard warranty against manufacturing defects. In case of any quality issues, please notify us within a specified period (e.g., 30 days post-delivery) for investigation and resolution, which may include replacement or credit. Our customer support team is available to assist with any concerns.

Conclusion

The strategic procurement of t shirt bags goes beyond merely selecting a functional item; it involves a comprehensive understanding of materials, manufacturing processes, industry standards, and environmental implications. For B2B decision-makers, choosing the right packaging solution, whether traditional HDPE or advanced compostable and reusable t shirt bags, directly impacts operational efficiency, brand perception, and sustainability goals. By leveraging customization options, businesses can transform these essential items into powerful marketing tools, enhancing customer experience and brand loyalty.

As the market continues to evolve towards more sustainable practices and stricter regulations, partnering with a knowledgeable and reputable manufacturer becomes paramount. This ensures access to high-quality, compliant, and cost-effective t shirt carry bags that meet the dynamic demands of modern commerce. Through informed choices, businesses can optimize their packaging strategy, contributing to both their bottom line and a more sustainable future.

References

- Grand View Research. "Plastic Bags and Sacks Market Size, Share & Trends Analysis Report By Product (T-Shirt Bags, Gusseted Bags), By End-use (Retail & Consumer, Institutional), By Region, And Segment Forecasts, 2023 - 2030."

- ASTM International. "ASTM D6400 - Standard Specification for Labeling of Plastics Designed to be Aerobically Composted in Municipal or Industrial Facilities."

- European Committee for Standardization (CEN). "EN 13432 - Packaging - Requirements for packaging recoverable through composting and biodegradation - Test scheme and evaluation criteria for the final acceptance of packaging."

- ISO. "ISO 9001:2015 - Quality management systems - Requirements."

- U.S. Food and Drug Administration (FDA). "Food Contact Substances (FCS) notifications."

-

Trash Bags: Choosing the Right Type and Buying in Bulk for Maximum EfficiencyNewsAug.11,2025

-

T-Shirt Bags: Lightweight, Durable, and Customizable for Retail and Food BusinessesNewsAug.11,2025

-

Poly Mailers: Lightweight, Durable Shipping for E-Commerce and LogisticsNewsAug.11,2025

-

Food Wrap Rolls & Wrapping Film: Cost-Effective Freshness for Food BusinessesNewsAug.11,2025

-

Bubble Mailers: Padded, Professional, and Ready to ShipNewsAug.11,2025

-

BOPP Bags: Durable, Printable Packaging for Bulk and Retail ProductsNewsAug.11,2025

-

Have the freedom of customizing your custom mailers any way you want! Our dedicated packaging support will help deliver you the mailing experience you need to elevate your shipping experience to the next level! Start making a strong impression on your customers and stand out from your competitors! -

LIYA uses high quality raw materials which directly purchased from large enterprises domestic and overseas such as PetroChina, Sinopec, Sabic, Equate, ExxonMobil, Dow Chemical, Total, and Borouge, ensuring the price advantage and quality of the raw materials. -

LIYA uses high quality raw materials which directly purchased from large enterprises domestic and overseas such as PetroChina, Sinopec, Sabic, Equate, ExxonMobil, Dow Chemical, Total, and Borouge, ensuring the price advantage and quality of the raw materials.