cpp polypropylene

An Overview of CPP (Cast Polypropylene) Properties, Applications, and Benefits

Cast Polypropylene (CPP) is a versatile thermoplastic polymer known for its unique properties and widespread applications across various industries. Unlike other polypropylenes, CPP is specifically manufactured using a cast film process, which lends it distinct advantages that make it an ideal choice for numerous applications.

Properties of CPP

CPP exhibits remarkable characteristics that set it apart from other materials. One of its most notable properties is its excellent clarity and transparency, making it a preferred choice for packaging applications where product visibility is crucial. This transparency is accompanied by a smooth surface finish, which not only enhances aesthetic appeal but also facilitates printing and labeling.

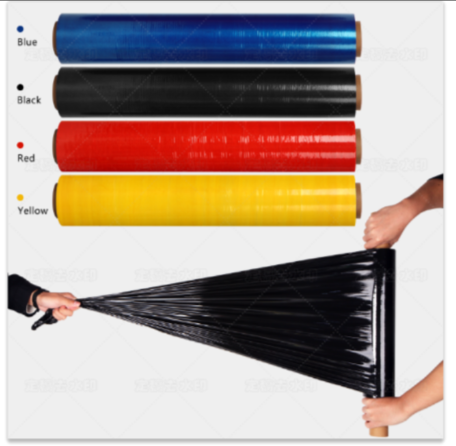

Flexibility is another key feature of CPP. The material possesses a lower tensile strength compared to other polymer types, allowing it to bend and conform to various shapes without breaking. This flexibility makes CPP an ideal candidate for applications requiring wrapping and layering, such as food packaging and protective films.

Additionally, CPP is known for its superior moisture barrier properties. It effectively protects products from moisture, which is essential for maintaining product quality and extending shelf life in food and pharmaceutical applications. Furthermore, CPP boasts excellent chemical resistance, allowing it to withstand exposure to various substances without degrading.

Applications of CPP

cpp polypropylene

The unique properties of CPP enable its use in a myriad of applications. One of the most prominent areas where CPP shines is in the packaging industry. The film is commonly used in food packaging due to its transparency, moisture barrier, and flexibility. CPP is often used for wraps, bags, and pouches that store snacks, fresh produce, and processed foods, ensuring that products remain fresh and visually appealing.

In the textile industry, CPP is utilized in making non-woven fabrics. Its lightweight and durable nature makes it suitable for producing shopping bags, blankets, and medical supplies. Furthermore, the film’s printing capabilities make it an attractive substrate for graphic packaging designs.

The electronics sector also benefits from CPP's properties, as it is employed in the manufacturing of protective films that shield screens and surfaces from scratches and damage. CPP films are often used in the production of overlays and graphics for electronic devices.

Benefits of CPP

The benefits of CPP extend beyond its physical properties and applications. One significant advantage is its environmental friendliness. CPP is fully recyclable, contributing to sustainability efforts in packaging materials. Recycling protocols for CPP help reduce waste while promoting a circular economy.

Moreover, CPP's cost-effectiveness makes it an appealing choice for manufacturers. The material’s ability to enhance product design without adding significant costs allows businesses to improve their offerings without straining budgets. Its durability also means reduced waste due to fewer product damages during transportation and handling.

In conclusion, Cast Polypropylene (CPP) is a remarkable material characterized by its clarity, flexibility, and moisture barrier properties. Its diverse applications, from food packaging to textiles and electronics, underscore its significance in various industries. As sustainability becomes increasingly important, CPP's recyclable nature further enhances its appeal. The unique benefits of CPP position it as a valuable player in the world of materials, promising continued innovation and application in the years to come.

-

Have the freedom of customizing your custom mailers any way you want! Our dedicated packaging support will help deliver you the mailing experience you need to elevate your shipping experience to the next level! Start making a strong impression on your customers and stand out from your competitors! -

LIYA uses high quality raw materials which directly purchased from large enterprises domestic and overseas such as PetroChina, Sinopec, Sabic, Equate, ExxonMobil, Dow Chemical, Total, and Borouge, ensuring the price advantage and quality of the raw materials. -

LIYA uses high quality raw materials which directly purchased from large enterprises domestic and overseas such as PetroChina, Sinopec, Sabic, Equate, ExxonMobil, Dow Chemical, Total, and Borouge, ensuring the price advantage and quality of the raw materials.