Wholesale Custom Printed T-Shirt Bags - Reusable & Durable

Introduction to Advanced T-Shirt Bag Solutions

In the dynamic landscape of modern retail and packaging, the humble t shirt bags have evolved into a critical component of supply chain logistics and brand presentation. These ubiquitous carryalls, named for their distinctive handle design, are indispensable for groceries, take-out food, and general merchandise. As businesses navigate increasing consumer demand for convenience coupled with a heightened focus on sustainability, the selection of appropriate t-shirt bag solutions becomes a strategic imperative. This comprehensive analysis delves into the technical aspects, market trends, and bespoke opportunities surrounding high-performance t-shirt bags, designed to meet the rigorous demands of B2B applications.

Modern manufacturing advancements have transformed standard bags into sophisticated packaging tools. From advanced polymer science to precision conversion technologies, today's t shirt bags offer superior tensile strength, puncture resistance, and aesthetic versatility. Understanding these technical nuances is crucial for procurement managers and operational specialists seeking optimal value and performance for their organizations.

Industry Trends and Market Dynamics for T-Shirt Carry Bags

The market for t shirt carry bags is undergoing significant transformation, primarily driven by environmental regulations, consumer preferences, and technological innovation. Key trends include the surging demand for reusable t shirt bags, the integration of biodegradable materials, and the increasing sophistication of custom branding options. According to a recent report by Grand View Research, the global plastic bags and sacks market size was valued at USD 26.5 billion in 2022 and is projected to grow at a compound annual growth rate (CAGR) of 4.3% from 2023 to 2030, with a substantial portion attributed to retail and food service packaging.

- Sustainability Mandates: Governments worldwide are implementing bans or taxes on single-use plastic bags, accelerating the shift towards eco-friendly alternatives. This has significantly boosted the adoption of compostable polymers (e.g., PLA, PHA) and durable reusable materials like non-woven polypropylene.

- Consumer Preference: A growing segment of environmentally conscious consumers actively seeks out retailers who offer sustainable packaging solutions. This drives brands to invest in greener t shirt bags to enhance their corporate social responsibility profile.

- Technological Advancements: Innovations in polymer science allow for thinner, yet stronger films, reducing material usage while maintaining performance. Advanced printing techniques also enable high-resolution graphics, turning bags into effective marketing tools.

- Supply Chain Optimization: Manufacturers are focusing on efficient production processes and streamlined logistics to reduce costs and lead times, particularly for large-volume orders of custom printed plastic t shirt bags wholesale.

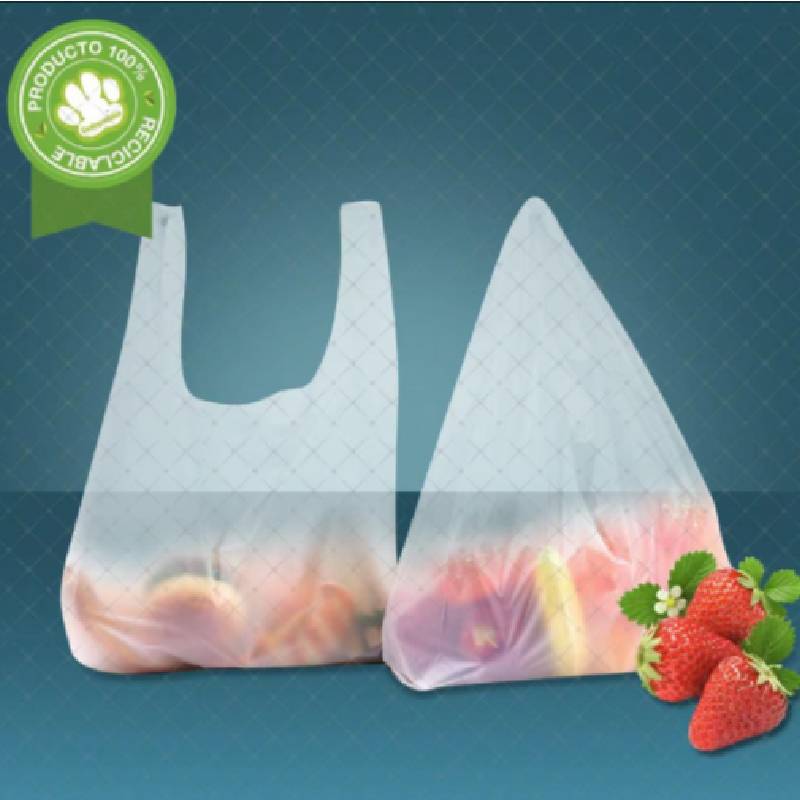

Figure 1: High-quality, durable t shirt bags ready for distribution.

Technical Specifications and Material Science of T-Shirt Bags

The performance of t shirt bags hinges critically on their material composition and structural engineering. The primary materials utilized include high-density polyethylene (HDPE), low-density polyethylene (LDPE), linear low-density polyethylene (LLDPE), and an increasing array of bioplastics such as polylactic acid (PLA), polyhydroxyalkanoates (PHA), and starch-based polymers. Each material offers distinct characteristics:

- HDPE Bags: Known for their high tensile strength-to-density ratio, HDPE bags are thin, strong, and crinkly. They offer excellent moisture barrier properties and are cost-effective for high-volume applications. Common gauges range from 0.4 mil to 0.8 mil.

- LDPE/LLDPE Bags: These bags are softer, more stretchable, and have a higher puncture resistance. Their clarity makes them suitable for applications where product visibility is desired. Gauges typically range from 0.8 mil to 2.0 mil for enhanced durability or print quality.

- Biodegradable/Compostable Bags: Manufactured from biopolymers, these bags meet specific composting standards (e.g., ASTM D6400 in North America, EN 13432 in Europe). They offer an eco-friendly alternative, designed to break down into natural elements in industrial composting facilities.

Key Technical Parameters:

- Gauge (Thickness): Measured in mils (thousandths of an inch) or microns. Directly impacts load bearing capacity and puncture resistance.

- Tensile Strength: The maximum stress a material can withstand while being stretched or pulled before breaking. Critical for preventing bag failure under heavy loads.

- Elongation at Break: The percentage increase in length before failure, indicating flexibility and stretch.

- Puncture Resistance: Ability to resist penetration by sharp objects, crucial for contents with irregular shapes.

- Seal Integrity: The strength and consistency of the heat-sealed seams, preventing bottom or side failures.

- Coefficient of Friction (COF): Affects stackability and ease of opening; lower COF for easier separation, higher for more stable stacking.

Figure 2: Biodegradable reusable t shirt bags, emphasizing sustainability.

The Manufacturing Process of High-Performance T-Shirt Bags

The production of high-quality t shirt bags involves a sophisticated multi-stage process, meticulously controlled to ensure consistency and performance. Unlike casting or forging processes used in metallurgy, bag manufacturing relies on polymer extrusion and conversion techniques. Our facilities adhere to stringent quality management systems, including ISO 9001:2015, ensuring product reliability from raw material to finished good.

Process Flow Schematic:

-

Raw Material Sourcing & Compounding:

High-grade polymer resins (e.g., HDPE, LDPE, biodegradable compounds) are sourced from reputable suppliers. These pellets are then often compounded with additives such as colorants, anti-block agents, and slip agents to achieve desired film characteristics and printability.

-

Film Extrusion (Blown Film Process):

The compounded pellets are fed into an extruder, where they are melted by heat and shear forces. The molten polymer is then forced through an annular die to form a continuous tube (bubble) of film. This bubble is air-cooled and collapsed to form a lay-flat tube, which is then wound onto jumbo rolls. Film thickness (gauge) is precisely controlled during this stage.

Technical Note: For optimal strength, some films undergo biaxial orientation during the blowing process, which aligns polymer chains in both machine and transverse directions, enhancing tensile strength and tear resistance. -

Printing (Flexographic/Rotogravure):

For custom printed t shirt bags wholesale, the lay-flat film is fed into high-speed printing presses. Flexographic printing is commonly used for its efficiency and ability to print on flexible substrates, accommodating multiple colors and intricate designs. Rotogravure printing offers even higher resolution and consistency for premium branding.

-

Bag Converting (Cutting & Sealing):

The printed or unprinted film rolls are transferred to bag-making machines. These machines automatically unwind the film, cut it to the desired length, and then heat-seal the bottom and sides to form the bag structure. Simultaneously, the signature "t-shirt" handles are punched out. Precision cutting and sealing ensure consistent bag dimensions and robust seal integrity.

-

Quality Control & Testing:

Each batch undergoes rigorous quality control. Testing includes measuring gauge, bag dimensions, tensile strength (ASTM D882), tear resistance (ASTM D1922), puncture resistance, and seal strength (ASTM F88). For biodegradable bags, disintegration and biodegradation tests (e.g., ASTM D6400, EN 13432) are performed by accredited third-party laboratories to ensure compliance.

-

Packaging & Distribution:

Finished bags are neatly stacked, counted, and packaged into master cartons or bales, ready for shipment. Careful packaging protects the bags during transit and ensures ease of handling for clients.

Figure 3: Automated production line for t shirt carry bags, ensuring high volume and quality.

Technical Advantages of Modern T-Shirt Bag Solutions

Contemporary t shirt bags offer a suite of technical advantages over traditional counterparts, contributing to enhanced operational efficiency, improved customer experience, and reduced environmental impact.

- Superior Strength-to-Weight Ratio: Through advanced polymer formulations and co-extrusion technologies, bags achieve high load capacities with minimal material, reducing source material consumption and freight costs.

- Optimized Puncture and Tear Resistance: Engineered film structures provide robust protection against internal and external stressors, minimizing product damage and returns, especially for irregularly shaped items in grocery or hardware retail.

- Enhanced Print Fidelity: Surface treatments (e.g., corona treatment) and high-definition flexographic printing allow for vibrant, long-lasting brand imagery, transforming each bag into a mobile advertisement for custom printed t shirt bags wholesale.

- Consistent Dispensing: Precision manufacturing ensures consistent bag opening and reliable dispensing from commercial bag racks, speeding up checkout processes and reducing operational friction.

- Sustainability Credentials: The availability of certified biodegradable and compostable options, alongside reusable t shirt bags made from recycled content, enables businesses to meet stringent environmental goals and consumer expectations.

- Moisture and Chemical Resistance: Depending on the polymer used, bags can offer excellent resistance to moisture, oils, and certain chemicals, crucial for food service and industrial applications.

Application Scenarios and Target Industries

T shirt bags are ubiquitous across a broad spectrum of industries, serving diverse functional requirements. Their versatility, combined with their cost-effectiveness and customizable nature, makes them a preferred choice for numerous B2B sectors.

- Grocery Retail: The primary application for traditional and reusable t shirt bags, accommodating a wide variety of grocery items, from fresh produce to canned goods. High load capacity and easy handling are paramount.

- Food Service & Takeout: Essential for restaurants, cafes, and delivery services for packaging multiple food container111s securely. Bags often feature enhanced leak resistance and heat retention properties.

- General Merchandise & Department Stores: Used for clothing, electronics, books, and various consumer goods, often opting for custom printed t shirt bags wholesale to elevate brand image.

- Pharmaceutical & Healthcare: While often specialized, certain non-sterile applications can utilize specific formulations of t-shirt bags for dispensing non-critical items.

- Agriculture & Produce Markets: For packaging bulk produce, requiring durability and sometimes breathability.

- Hardware & Home Improvement: Robust bags are needed for heavier or sharp-edged items, demanding high puncture resistance.

Figure 4: Custom printed plastic t shirt bags for effective brand promotion.

Customized Solutions: Tailoring T-Shirt Bags for Your Brand

For businesses seeking to maximize their brand presence and meet specific operational needs, customized t shirt bags offer unparalleled advantages. Our expertise in custom printed plastic t shirt bags wholesale and custom printed t shirt bags wholesale allows for bespoke solutions that perfectly align with corporate identity and functional requirements.

Customization Parameters:

- Dimensions: Tailored width, height, and gusset sizes to fit specific product ranges or packaging volumes, optimizing material use and reducing waste.

- Material & Gauge: Selection from HDPE, LDPE, LLDPE, or various biodegradable/compostable polymers, with precise gauge control to balance strength, cost, and environmental impact.

- Color & Print: Full-color custom printing capabilities (up to 8 colors) using flexographic or rotogravure methods for sharp logos, intricate designs, and promotional messages. Pantone matching ensures brand consistency.

- Additives: Options for anti-static agents (for electronics), UV stabilizers (for outdoor use), or anti-microbial additives (for specific healthcare or food applications).

- Handle Reinforcement: For exceptionally heavy loads, options for reinforced handles or thicker gauges at stress points can be implemented to prevent tearing.

- Packaging & Dispensing: Custom counts per roll or carton, designed for compatibility with existing dispensing systems or specific retail shelving requirements.

Our design team works collaboratively with clients, from initial concept to final production, ensuring that every specification is met with precision and innovation. This bespoke approach transforms a functional item into a powerful branding tool, reinforcing customer loyalty and market visibility.

Product Specification Table: Standard T-Shirt Bags

Below are typical specifications for our standard range of t shirt bags, demonstrating the balance of strength, utility, and environmental consideration available. Custom specifications vary.

| Parameter | Value/Range (HDPE) | Value/Range (LDPE) | Value/Range (Compostable) |

|---|---|---|---|

| Material Type | High-Density Polyethylene | Low-Density Polyethylene | PLA/PBAT/Starch Blend |

| Standard Sizes (W x H + Gusset) | 11"x22" +6", 12"x24"+7" | 12"x24" +7", 15"x28"+8" | 12"x24" +7", 15"x28"+8" |

| Gauge/Thickness | 0.4 - 0.7 mil (10-18 microns) | 0.8 - 1.5 mil (20-38 microns) | 0.9 - 1.8 mil (23-45 microns) |

| Load Capacity (Approx.) | 10-15 lbs (4.5-6.8 kg) | 15-25 lbs (6.8-11.3 kg) | 12-20 lbs (5.4-9.1 kg) |

| Tensile Strength (MD/TD) | >15 MPa / >10 MPa | >10 MPa / >10 MPa | >12 MPa / >8 MPa |

| Elongation at Break | 100-300% | 300-600% | 150-400% |

| Printing Options | Up to 8 colors Flexographic | Up to 8 colors Flexographic/Rotogravure | Up to 6 colors Flexographic |

| Environmental Certifications | Recyclable (where facilities exist) | Recyclable (where facilities exist) | ASTM D6400, EN 13432 Certified |

Vendor Comparison: Selecting the Right Partner for Your T-Shirt Bags

Choosing the right manufacturer for your t shirt bags is a strategic decision that impacts quality, cost-efficiency, and brand reputation. Key differentiators extend beyond unit price to encompass technical expertise, production capabilities, quality assurance, and after-sales support.

| Feature/Criterion | Our Company (Liya BioBag) | Typical Competitor A (Standard Producer) | Typical Competitor B (Budget Producer) |

|---|---|---|---|

| Material Innovation | Extensive R&D in bioplastics (PLA, PHA, Starch), advanced HDPE/LDPE blends, PCR content. | Standard HDPE/LDPE, limited bioplastic range. | Primarily virgin HDPE/LDPE, minimal sustainable options. |

| Customization & Printing | Full custom sizes, 8-color HD Flexographic/Rotogravure, graphic design support. | Limited custom sizes, 4-6 color Flexographic, basic design support. | Standard sizes only, 1-2 color basic printing. |

| Quality Assurance & Certifications | ISO 9001, ASTM D6400, EN 13432, FDA Food Contact (relevant grades), rigorous in-house testing. | Basic QC, some general certifications (e.g., ISO 9001). | Minimal QC, few formal certifications. |

| Lead Time & Fulfillment | Optimized production for consistent 3-5 week lead times, global logistics. | 4-7 weeks, may vary based on order size. | 6-10 weeks, often extended for complex orders. |

| Customer Support & Warranty | Dedicated account managers, 100% satisfaction guarantee, responsive after-sales. | Standard support, limited warranty. | Transactional, minimal post-purchase support. |

| Sustainability Focus | Core business model emphasizes eco-friendly solutions, actively promotes reusable t shirt bags. | Offers some eco-options, but not primary focus. | Cost-driven, sustainability secondary. |

Figure 5: High-definition custom printed t shirt bags, showcasing advanced branding capabilities.

Application Case Studies: Real-World Impact of Advanced T-Shirt Bags

The practical application of high-performance t shirt bags yields tangible benefits across various commercial sectors. Here are illustrative case studies highlighting their impact:

Case Study 1: Large Regional Grocery Chain – Transition to High-Strength HDPE Bags

Client Profile: A major regional grocery chain operating over 150 stores, seeking to reduce bag breakage rates and enhance customer satisfaction without significantly increasing costs.

Challenge: Previous supplier's bags exhibited high failure rates (approx. 2-3% of transactions reported bag breakage), leading to customer complaints and potential product loss. Bags were often doubled, increasing material consumption.

Solution: We provided custom-engineered HDPE t shirt bags with an optimized gauge and enhanced polymer blend, specifically designed for improved tensile strength and tear resistance. These bags were tested rigorously to exceed the chain's typical load requirements by 25%.

Results:

- Bag Breakage Reduced: Incidents dropped by over 80% within the first six months, significantly improving customer experience.

- Material Efficiency: The need for double-bagging was nearly eliminated, resulting in a 15% reduction in total bag consumption annually.

- Cost Savings: Despite a slight increase in per-bag cost, the overall expenditure on bags decreased by 8% due to reduced usage and fewer customer service issues.

Case Study 2: Fast-Casual Restaurant Franchise – Adoption of Custom Printed Compostable T-Shirt Bags

Client Profile: A rapidly expanding fast-casual restaurant franchise committed to sustainable practices, seeking to align its packaging with its eco-friendly brand image.

Challenge: The franchise wanted to eliminate conventional plastic bags for takeout orders but required a solution that maintained functionality (load capacity, leak resistance) and offered strong branding opportunities.

Solution: We developed custom-sized, fully compostable t shirt carry bags made from a PLA/PBAT blend, certified to EN 13432 and ASTM D6400 standards. These bags were custom-printed with the franchise’s vibrant logo and a clear "Compostable" message, reinforcing their sustainability efforts.

Results:

- Enhanced Brand Image: Positive media coverage and customer feedback regarding their commitment to sustainability.

- Regulatory Compliance: Successfully met local and national compostable packaging mandates, avoiding potential fines and enhancing market access.

- Functionality Maintained: Bags performed comparably to traditional plastic in terms of strength and liquid resistance for typical takeout orders.

- Marketing Impact: The visually appealing custom printed t shirt bags wholesale acted as walking billboards, increasing brand visibility.

Frequently Asked Questions (FAQ) about T-Shirt Bags

- Q1: What are the primary material differences between HDPE and LDPE t shirt bags?

- A1: HDPE bags are typically thinner, crinklier, and possess higher tensile strength, making them ideal for carrying heavy or dense items. LDPE bags are softer, more elastic, offer superior puncture resistance, and are clearer, making them suitable for items that may have sharp edges or where visibility is desired.

- Q2: Are your biodegradable t shirt bags truly compostable?

- A2: Yes, our biodegradable bags are rigorously tested and certified to international composting standards such as ASTM D6400 (North America) and EN 13432 (Europe). This means they are designed to break down completely in industrial composting facilities, leaving no harmful residues.

- Q3: What is the typical lead time for custom printed t shirt bags wholesale orders?

- A3: For custom printed orders, the lead time typically ranges from 3 to 5 weeks from final artwork approval and deposit. This includes production, quality control, and shipping preparation. Expedited options may be available depending on order volume and current production schedules.

- Q4: How can I ensure the design on my custom printed plastic t shirt bags wholesale is consistent?

- A4: We utilize advanced flexographic and rotogravure printing technologies with precise color matching (Pantone system) and strict quality control checks at every stage. We also provide digital proofs and, upon request, physical samples for approval before full production to ensure design consistency.

- Q5: What are the minimum order quantities (MOQ) for custom bags?

- A5: MOQs vary depending on the material, size, and complexity of printing. Generally, for custom printed bags, MOQs start from 25,000 to 50,000 units. Please contact our sales team for specific details tailored to your requirements.

Lead Time, Warranty, and Customer Support

At Liya BioBag, we are committed to providing exceptional service and reliable products. Our operational framework is designed to instill confidence and ensure a seamless procurement experience for all clients.

Lead Time & Fulfillment:

Standard lead times for unprinted t shirt bags range from 2-3 weeks. For custom printed or specialized biodegradable orders, lead times are typically 3-5 weeks post-artwork approval. We maintain robust supply chain management and work with established logistics partners to ensure timely delivery globally. For urgent requirements, please discuss expedited production options with your account manager.

Quality Assurance & Warranty:

All our t shirt bags undergo stringent quality control processes in accordance with ISO 9001:2015 standards. We offer a comprehensive warranty against manufacturing defects and material failures under normal use conditions for a period of 12 months from the date of shipment. This warranty covers issues related to material integrity, seal strength, and print durability. Any claims are promptly investigated by our technical team, with solutions ranging from replacement to credit issuance.

Dedicated Customer Support:

Our commitment extends beyond delivery. Each client is assigned a dedicated account manager who serves as a single point of contact for all inquiries, from order placement to technical support and after-sales service. Our support team is available during business hours to address any concerns, provide technical specifications, and assist with reordering. We pride ourselves on responsive communication and proactive problem-solving.

Conclusion

The modern t shirt bags market is defined by innovation, sustainability, and an unwavering demand for performance. As industries evolve and environmental stewardship gains precedence, partnering with a manufacturer capable of delivering technically advanced, customizable, and ethically produced packaging solutions is paramount. Our extensive range of materials, state-of-the-art manufacturing processes, and commitment to quality ensure that businesses can confidently meet their operational demands while enhancing their brand's appeal and environmental footprint. Embrace the future of packaging with solutions engineered for excellence and tailored for success.

References

- Grand View Research. (2023). Plastic Bags and Sacks Market Size, Share & Trends Analysis Report By Product, By Raw Material, By Application, By Region, And Segment Forecasts, 2023 - 2030.

- ASTM International. (2022). ASTM D6400-22, Standard Specification for Labeling of Plastics Designed to be Aerobically Composted in Municipal or Industrial Facilities.

- European Committee for Standardization (CEN). (2018). EN 13432:2000, Packaging - Requirements for packaging recoverable through composting and biodegradation - Test scheme and evaluation criteria for the final acceptance of packaging.

- ISO. (2015). ISO 9001:2015 Quality management systems — Requirements.

- Plastic Industry Association. (2023). "Innovations in Sustainable Plastics."

-

Wholesale Custom Printed T-Shirt Bags - Reusable & DurableأخبارSep.01,2025

-

Sustainable Biodegradable Paper Coffee Cups | Eco-FriendlyأخبارAug.31,2025

-

Premium Handle Film for Effortless & Secure PackagingأخبارAug.30,2025

-

Durable Silage Bale Wrap Film | Premium Forage PreservationأخبارAug.29,2025

-

Premium Poly Mailer Bags - Secure & Lightweight Shipping SolutionsأخبارAug.28,2025

-

No-Sew Methods for Making a Drawstring BagأخبارAug.22,2025

-

تمتع بحرية تخصيص رسائل البريد المخصصة الخاصة بك بالطريقة التي تريدها! سيساعدك دعم التغليف المخصص لدينا على توفير تجربة البريد التي تحتاجها للارتقاء بتجربة الشحن الخاصة بك إلى المستوى التالي! ابدأ في ترك انطباع قوي لدى عملائك وتميز عن منافسيك! -

تستخدم LIYA مواد خام عالية الجودة يتم شراؤها مباشرة من المؤسسات الكبيرة المحلية والخارجية مثل PetroChina، وSinopec، وSabic، وEquate، وExxonMobil، وDow Chemical، وTotal، وBorouge، مما يضمن الميزة السعرية وجودة المواد الخام. -

تستخدم LIYA مواد خام عالية الجودة يتم شراؤها مباشرة من المؤسسات الكبيرة المحلية والخارجية مثل PetroChina، وSinopec، وSabic، وEquate، وExxonMobil، وDow Chemical، وTotal، وBorouge، مما يضمن الميزة السعرية وجودة المواد الخام.