Custom Printed T Shirt Bags Wholesale | Reusable Carry Bags

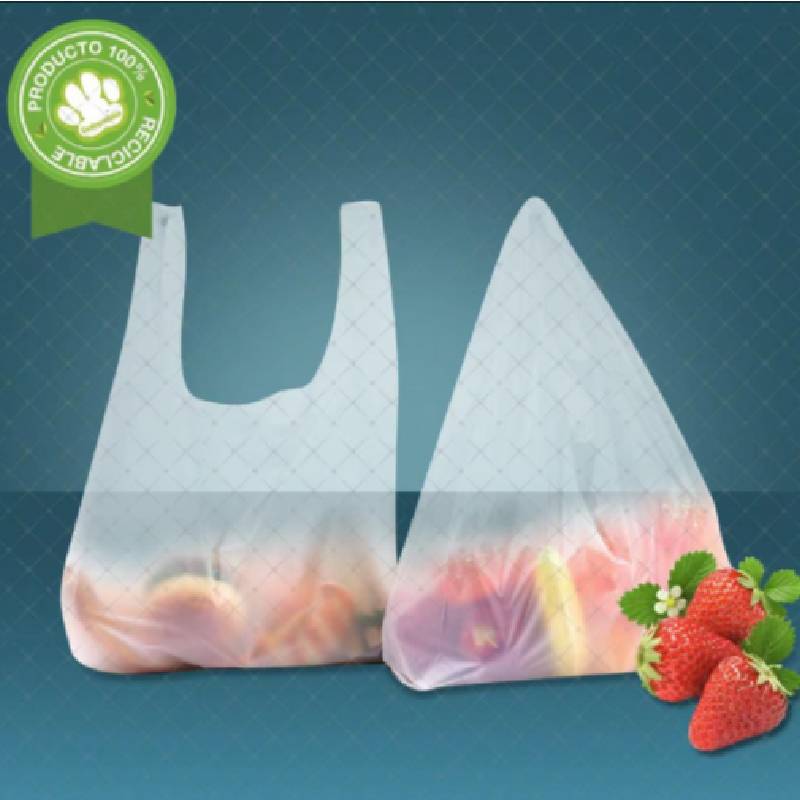

In today's dynamic retail and food service sectors, the demand for versatile and reliable packaging solutions is paramount. Among these, t shirt bags stand out as an indispensable item, known for their distinctive handle design and high utility. These bags, often referred to as thick grocery bags or take-out food plastic bags, offer a practical and efficient means for transporting goods. As a leading manufacturer, our commitment lies in producing bags that not only meet but exceed industry standards for durability, functionality, and sustainability. This comprehensive guide delves into the intricate aspects of T-shirt bags, exploring their manufacturing processes, technical specifications, diverse applications, and the competitive advantages they offer to businesses operating across various industries, from retail to specialized logistics.

Industry Trends in T-shirt Bag Manufacturing

The global market for t shirt bags is currently undergoing significant transformation, primarily driven by evolving consumer preferences and stringent environmental regulations. A notable trend is the rapid shift towards sustainable alternatives, with a growing emphasis on reusable t shirt bags and those made from biodegradable or compostable materials. This push is fueled by increasing awareness of plastic pollution and the desire for eco-friendly packaging solutions. Innovations in polymer science are enabling the development of bags that maintain the strength and convenience of traditional plastic while offering a reduced environmental footprint. Furthermore, the rise of e-commerce and home delivery services has significantly increased the demand for robust and reliable t shirt carry bags capable of handling diverse product weights and shapes. Brands are also leveraging custom printing capabilities to enhance their marketing efforts, transforming a utilitarian item into a powerful branding tool.

Technological advancements in manufacturing processes, such as improved film extrusion and high-definition flexographic printing, are allowing for greater efficiency and product quality. Manufacturers are also focusing on optimizing supply chains to meet the high-volume demands of wholesale clients, ensuring timely delivery and competitive pricing. The market is seeing an increased specialization, with providers offering tailored solutions for specific industries, from heavy-duty grocery bags to specialized bags for pharmaceuticals or delicate items. The long-term outlook for the t shirt bags sector points towards continued innovation in materials, design, and manufacturing practices, all aimed at balancing cost-effectiveness with environmental responsibility and superior functionality.

Technical Parameters and Specifications

The performance of t shirt bags is defined by a precise set of technical parameters, crucial for ensuring their suitability across various applications. Key specifications include material composition, thickness (measured in microns or mils), tensile strength, tear resistance, and load capacity. Our bags are primarily manufactured from High-Density Polyethylene (HDPE), Low-Density Polyethylene (LDPE), or linear low-density polyethylene (LLDPE) for exceptional strength-to-weight ratio, or from compostable polymers like PBAT and PLA for eco-friendly options. The choice of material directly impacts the bag's elasticity, puncture resistance, and opacity.

Thickness is a critical factor, with standard grocery bags often ranging from 0.4 mil to 1.2 mil (approximately 10 to 30 microns). Thicker bags offer enhanced durability and load-bearing capabilities, making them ideal for heavier items or multiple uses. Load capacity, typically expressed in pounds or kilograms, is determined through rigorous testing protocols to guarantee bags can withstand intended weights without tearing or handles failing. Print quality, measured in dots per inch (DPI) and color registration, is vital for custom printed t shirt bags wholesale, ensuring vibrant, consistent branding. Bags designed for food contact adhere to FDA or equivalent food safety standards, guaranteeing no harmful leachates. Our production adheres to ISO 9001 quality management standards, ensuring consistent product performance.

Typical T-shirt Bag Specifications

| Parameter | Value Range | Description |

|---|---|---|

| Material Type | HDPE, LDPE, LLDPE, Bio-degradable (PBAT+PLA) | Determines strength, flexibility, and environmental impact. HDPE for crispiness, LDPE for softness. |

| Thickness | 10-50 Microns (0.4-2.0 Mils) | Higher microns indicate thicker, stronger bags. Custom thicknesses available. |

| Width | 10 - 30 inches (25 - 75 cm) | Measured flat. Includes side gussets for increased volume. |

| Height | 15 - 40 inches (38 - 100 cm) | Total height including handles. |

| Load Capacity | Up to 25 lbs (11 kg) for standard grocery size | Varies with material, thickness, and bag dimensions. |

| Print Colors | Up to 8 colors (Flexographic Printing) | High-definition printing for vivid logos and designs. |

| Certifications | ISO 9001, FDA (for food contact), ASTM D6400 (compostable) | Ensures quality, safety, and environmental compliance. |

The Manufacturing Process of T-shirt Bags

The production of t shirt bags is a sophisticated, multi-stage process that begins with raw polymer pellets and culminates in precisely formed, often custom-printed bags. This detailed manufacturing process ensures consistency, strength, and the desired aesthetic qualities of the final product.

Process Flow Explained:

- Resin Granule Feeding: High-grade HDPE, LDPE, LLDPE, or biodegradable resin granules are fed into an extrusion machine. Pigments and additives (e.g., slip agents, anti-block agents) are precisely measured and mixed to achieve the desired color and film properties.

- Film Extrusion (Blown Film): The mixed resin is melted and extruded through a circular die, forming a continuous tube of molten plastic. This tube is then inflated with air (blown film process) to create a bubble, which is stretched both axially and radially to the desired thickness. This bi-axial orientation enhances the film's tensile strength and barrier properties. The bubble is then flattened and wound onto rolls.

- Printing (Flexographic): For custom printed plastic t shirt bags wholesale, the film rolls proceed to high-speed flexographic printing presses. This process uses flexible relief plates and fast-drying inks to print designs, logos, and branding onto the film. Multi-color printing up to 8 colors can be achieved with high precision, ensuring brand consistency and visual appeal. Advanced systems monitor print registration to prevent misalignment.

- Cutting and Sealing: The printed or unprinted film rolls are then fed into a specialized T-shirt bag making machine. This machine automatically folds the film, forms the side gussets, heat-seals the bottom, and punches out the distinctive T-shirt shaped handles. Ultrasonic sealing technology can be employed for stronger, more consistent seams.

- Perforation and Stacking: Individual bags are then perforated at the top for easy detachment from rolls or stacked in precise quantities (e.g., 500 or 1000 bags per bundle) for bulk packaging.

- Quality Control & Packaging: Throughout the entire process, rigorous quality control checks are performed. This includes visual inspections for print quality, bag integrity, and measurements to ensure adherence to specified dimensions and thickness. Tensile strength and tear resistance tests are conducted on samples using standardized methods (e.g., ASTM D882 for tensile properties). Completed bundles are then packaged into master cartons, ready for shipment.

Our manufacturing facilities utilize state-of-the-art equipment and adhere to strict environmental protocols. The average service life of a standard HDPE t shirt bag is designed for single or multiple uses, while reusable t shirt bags are engineered for hundreds of cycles, offering exceptional durability. Applicable industries for our T-shirt bags include supermarkets, grocery stores, restaurants (for takeout/delivery), retail boutiques, pharmacies, and general merchandise stores. Our products demonstrate superior performance in diverse scenarios, ensuring optimal load-bearing capacity and robust tear resistance even with bulky or irregular items, thus providing a reliable and cost-effective packaging solution.

Diverse Application Scenarios

The versatility of t shirt bags makes them an ideal choice for a wide array of industries requiring efficient and economical packaging. Their design, featuring integrated handles and expandable gussets, allows them to accommodate various items, from groceries to prepared meals.

- Retail & Grocery Stores: These are the most common applications, where t shirt bags serve as essential carry-out bags for purchased goods. Their robust construction ensures items like canned goods, produce, and boxed products are transported securely. The ability to customize these bags with store logos significantly enhances brand visibility and customer loyalty.

- Food Service & Take-out: Restaurants and fast-food establishments heavily rely on t shirt carry bags for food delivery and customer take-out orders. The bags' ability to stand upright when filled, along with their reliable handles, prevents spills and ensures food items arrive intact. Bags made from food-grade materials are essential in this sector.

- Healthcare & Pharmacies: For discreet and convenient packaging of prescriptions and medical supplies, these bags offer a practical solution. Their compact storage before use and ease of handling are key benefits.

- Small Businesses & Boutiques: Custom-printed t shirt bags provide an affordable yet impactful way for smaller retailers to present their products professionally and reinforce their brand identity.

- Special Events & Promotions: Used as giveaway bags at trade shows, conferences, or promotional events, they offer a convenient way for attendees to carry materials and serve as mobile advertisements for the sponsoring entity.

Technical Advantages and Benefits

Our t shirt bags offer a suite of technical advantages that translate directly into operational efficiencies and enhanced user satisfaction for B2B clients. These advantages stem from thoughtful design, selection of premium materials, and adherence to stringent manufacturing processes.

- Superior Load-Bearing Capacity: Engineered with reinforced side gussets and robust handle designs, our bags excel in carrying substantial weight without tearing. This is critical for grocery stores and businesses dealing with heavier merchandise, minimizing breakage and customer dissatisfaction.

- Exceptional Tear and Puncture Resistance: Utilizing high-grade HDPE or specific blends of LDPE, our bags exhibit remarkable resistance to tears and punctures, even when carrying items with sharp edges or irregular shapes. This reduces product loss and ensures items remain secure during transit.

- Space Efficiency: Despite their ample carrying capacity, t shirt bags are designed to be highly compact when empty, allowing for efficient storage in retail environments and minimizing shipping volume for wholesale orders.

- Optimal Print Surface: The smooth, consistent surface of our bags, particularly those made from LDPE or high-gloss HDPE, provides an excellent canvas for flexographic printing. This enables crisp, vibrant, and long-lasting custom branding, essential for businesses looking to enhance their market presence.

- Moisture and Leak Resistance: The non-porous nature of polyethylene ensures that contents are protected from external moisture, and any internal leaks (e.g., from take-out food) are contained, preventing damage to other items or surfaces.

- Cost-Effectiveness at Scale: Through optimized production lines and efficient material sourcing, we provide custom printed plastic t shirt bags wholesale at highly competitive prices, offering significant cost savings for bulk purchasers without compromising on quality or performance.

Customization Solutions for Your Brand

Recognizing that every business has unique branding and functional requirements, we offer extensive customization options for our t shirt bags. This allows clients to procure packaging that not only meets their operational needs but also serves as a powerful extension of their brand identity.

- Material Selection: Clients can choose from various materials, including conventional HDPE and LDPE, or opt for eco-friendly alternatives such as compostable (PBAT+PLA) or recycled content plastics. This flexibility allows businesses to align their packaging with their sustainability goals.

- Size and Thickness: Bags can be manufactured in a comprehensive range of dimensions (width, height, gusset depth) and thicknesses to suit the specific volume and weight of products. From small bags for delicate items to large, thick grocery bags, our capabilities cover diverse needs.

- Custom Printing: Our advanced flexographic printing capabilities allow for up to 8 colors, enabling high-resolution printing of intricate logos, marketing messages, and QR codes. This transforms each bag into a mobile advertisement for custom printed t shirt bags wholesale orders, enhancing brand recall and visibility.

- Color and Opacity: Bags can be produced in a wide spectrum of colors, including transparent, opaque, or tinted, to match brand guidelines or specific aesthetic preferences.

- Special Features: Options include perforations for easy dispensing from rolls, specific handle reinforcement for heavier loads, and addition of special additives for enhanced properties like UV resistance or anti-static qualities.

Our expert design and technical teams collaborate closely with clients to develop bespoke solutions, from initial concept to final production, ensuring that the customized t shirt bags precisely meet their functional and branding requirements.

Manufacturer Comparison: Key Differentiators

When sourcing t shirt bags, discerning B2B buyers must evaluate potential manufacturers based on several critical differentiators beyond just price. Our approach emphasizes a holistic value proposition that ensures long-term partnership success.

What Sets Us Apart:

| Feature | Our Commitment | Typical Industry Standard |

|---|---|---|

| Material Purity & Sourcing | Virgin, food-grade resins (HDPE/LDPE) and certified compostable polymers (PBAT+PLA) from reputable global suppliers. | Often use mixed or recycled materials without consistent quality checks, leading to variable strength. |

| Manufacturing Precision | State-of-the-art blown film extrusion and automated bag-making machines. Strict tolerance control for thickness and dimensions. | Older machinery, less precise control leading to inconsistent bag quality and higher defect rates. |

| Print Quality & Durability | High-definition flexographic printing (up to 8 colors) with fade-resistant inks, ensuring vibrant, long-lasting branding. | Basic printing, limited color options, prone to smudging or fading. |

| Certifications & Compliance | ISO 9001 certified. Food-contact bags meet FDA standards. Compostable bags meet ASTM D6400/EN 13432. | Minimal or no external certifications, relying solely on internal quality checks. |

| Customer Support & Lead Time | Dedicated account management, rapid prototyping, and consistent on-time delivery schedules (typical 3-4 weeks). | Slow response times, inconsistent lead times, and limited post-sales support. |

Our commitment to quality, innovation, and client partnership distinguishes us in the highly competitive market for t shirt bags. We prioritize long-term value over short-term gains, ensuring our clients receive a product that enhances their operations and reputation.

Real-World Application Cases

Our t shirt bags have been successfully integrated into the operations of numerous businesses across diverse sectors, demonstrating their adaptability and performance in practical settings. These application cases highlight how our tailored solutions provide tangible benefits to clients.

- Large Grocery Chain Partnership: A major national grocery chain transitioned to our thicker, 1.0 mil HDPE t shirt bags, custom-printed with their loyalty program promotions. This resulted in a 15% reduction in bag breakage complaints and a measurable increase in customer satisfaction scores related to checkout experience, as reported in their quarterly operational review. The enhanced durability also indirectly supported their push for reusable t shirt bags as customers found them more robust for multiple uses.

- Fast-Casual Restaurant Franchise: A rapidly expanding fast-casual dining franchise adopted our custom-sized, food-grade LDPE t shirt carry bags for their growing takeout and delivery service. The bags were designed with wider gussets to accommodate multiple food container111s securely, minimizing spillage during transit. This led to a 20% decrease in food delivery complaints stemming from packaging issues and contributed to positive online reviews regarding package integrity.

- Eco-Conscious Boutique Retailer: Partnering with a boutique committed to sustainability, we supplied custom printed t shirt bags wholesale made from certified compostable material. These bags, adorned with the boutique's elegant eco-friendly branding, enhanced the store's green image and resonated strongly with their target demographic, providing a premium, responsible packaging solution.

These instances underscore our capability to deliver high-quality, customized t shirt bags that meet specific industry demands and contribute directly to our clients' operational success and brand reputation.

Frequently Asked Questions (FAQ)

-

Q1: What materials are your t shirt bags made from?

A1: Our bags are primarily made from high-quality HDPE (High-Density Polyethylene) for crisp, strong bags, LDPE (Low-Density Polyethylene) for softer, more flexible options, and certified biodegradable/compostable polymers (PBAT+PLA) for eco-friendly solutions. -

Q2: Can I get custom printed t shirt bags wholesale with my company logo?

A2: Absolutely. We offer extensive custom printing services using advanced flexographic technology, capable of reproducing intricate designs and multiple colors (up to 8 colors) to perfectly match your brand's aesthetic. -

Q3: What is the typical lead time for a wholesale order of t shirt bags?

A3: Standard lead time for wholesale orders, including custom printing, is typically 3-4 weeks from final artwork approval. Expedited services may be available upon request. -

Q4: Are your bags suitable for food contact?

A4: Yes, we produce bags specifically designed for food contact applications, adhering to stringent FDA (Food and Drug Administration) or equivalent international food safety standards, ensuring they are safe for packaging food items. -

Q5: What are the minimum order quantities (MOQ) for custom bags?

A5: MOQs vary depending on the specific customization requirements (material, size, print complexity). Please contact our sales team for detailed information tailored to your needs.

Delivery and Quality Assurance

We understand the critical importance of timely delivery and unwavering quality in the B2B sector. Our logistics and quality control protocols are designed to ensure maximum reliability for every order of t shirt bags.

Delivery Cycle:

Our streamlined production and supply chain management enable efficient order fulfillment. For standard wholesale orders, the typical delivery cycle is 3-4 weeks from the confirmation of the order and approval of all specifications and artwork. This period includes material procurement, manufacturing, quality checks, and shipping preparation. For urgent requirements or very large volume orders, we work closely with clients to establish a realistic and achievable timeline. We offer various shipping options to meet diverse logistical needs, including sea freight for cost-effectiveness and air freight for expedited delivery.

Quality Warranty and Customer Support:

All our t shirt bags are manufactured under strict ISO 9001 certified quality management systems. We stand by the quality of our products with a comprehensive warranty against manufacturing defects. Should any issues arise that fall within our warranty terms, we are committed to prompt resolution, which may include replacement or credit. Our dedicated customer support team is available to assist with any inquiries, from technical specifications to order tracking and post-delivery support, ensuring a seamless experience for our B2B partners. Your satisfaction and trust are paramount to our business success.

References

- ASTM International. (2020). Standard Specification for Compostable Plastics. ASTM D6400-19.

- International Organization for Standardization. (2015). Quality management systems — Requirements. ISO 9001:2015.

- United States Food and Drug Administration. (2023). Food Contact Substances.

-

Drawstring Bags: Versatile, Customizable, and Cost-Effective for Bulk UseNewsAug.15,2025

-

Disposable Gloves: Wholesale Solutions for Safety, Hygiene, and EfficiencyNewsAug.15,2025

-

Trash Bags: Choosing the Right Type and Buying in Bulk for Maximum EfficiencyNewsAug.11,2025

-

T-Shirt Bags: Lightweight, Durable, and Customizable for Retail and Food BusinessesNewsAug.11,2025

-

Poly Mailers: Lightweight, Durable Shipping for E-Commerce and LogisticsNewsAug.11,2025

-

Food Wrap Rolls & Wrapping Film: Cost-Effective Freshness for Food BusinessesNewsAug.11,2025

-

Have the freedom of customizing your custom mailers any way you want! Our dedicated packaging support will help deliver you the mailing experience you need to elevate your shipping experience to the next level! Start making a strong impression on your customers and stand out from your competitors! -

LIYA uses high quality raw materials which directly purchased from large enterprises domestic and overseas such as PetroChina, Sinopec, Sabic, Equate, ExxonMobil, Dow Chemical, Total, and Borouge, ensuring the price advantage and quality of the raw materials. -

LIYA uses high quality raw materials which directly purchased from large enterprises domestic and overseas such as PetroChina, Sinopec, Sabic, Equate, ExxonMobil, Dow Chemical, Total, and Borouge, ensuring the price advantage and quality of the raw materials.