Jul . 29, 2025 21:00

Back to list

Self Seal Craft Bags - Clear, Food Safe, Easy Self Sealing Bags

Self seal craft bags have become an essential packaging innovation across various industries, providing a unique combination of convenience, product protection, and versatile customizability. This comprehensive guide delves into the latest market trends, technology standards, manufacturing processes, and real-world application cases of self seal craft bags, referencing the latest data and expert perspectives.

1. Industry Overview & Market Trends of Self Seal Craft Bags

In 2023, the global self seal craft bags market was valued at USD 1.8 billion and is projected to reach USD 2.7 billion by 2028, growing at a CAGR of 7.2% (MRFR Report). The rising demand for sustainable, food-safe, and customizable packaging has fueled significant innovation, especially in craft designer self sealing bags and clear plastic self sealing bags. Enhanced features like eco-friendliness, moisture barriers, and anti-static properties cater to industries such as food, pharmaceuticals, and electronics.

2. Product Classification & Technical Parameter Table

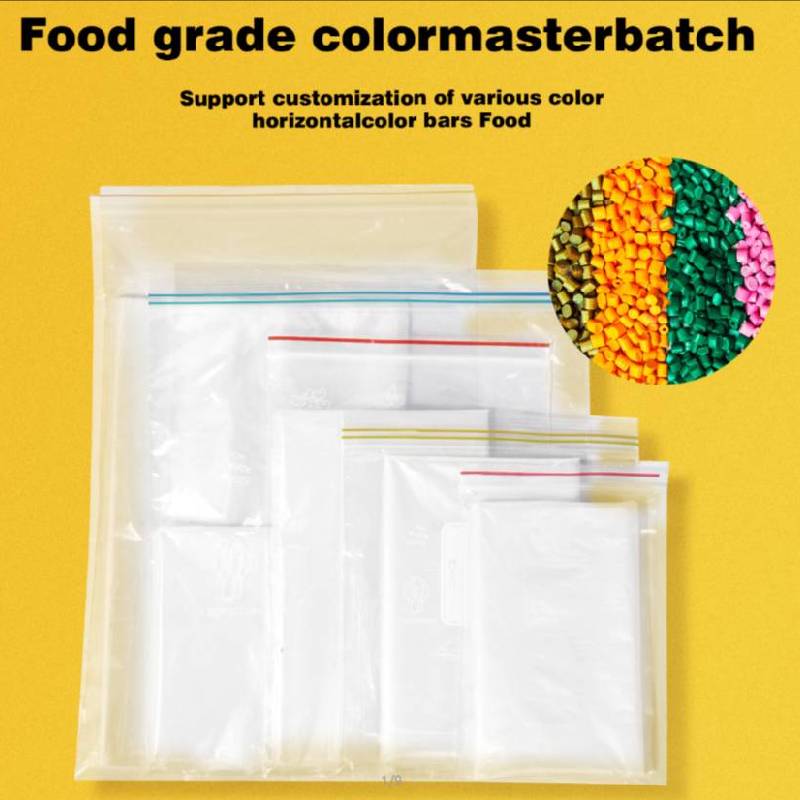

Self seal craft bags come in a variety of types, including transparent, matte, anti-static, zip-lock, and food-grade variants. Each serves industries ranging from food packaging to electronics and apparel.

| Type | Material | Thickness (μm) | Available Sizes (mm) | Closure Type | Certifications | Typical Applications |

|---|---|---|---|---|---|---|

| Craft Designer Self Sealing Bags | CPP/BOPP | 35-70 | 50×80 – 350×450 | Self-adhesive | ISO 9001, FSC | Stationery, handicraft, jewelry |

| Clear Plastic Self Sealing Bags | LDPE/HDPE | 30-100 | 60×100 – 500×700 | Peel & Seal | ISO 22000, REACH | Food, garments, electronics |

| Self Sealing Bags for Food | Food-grade PE | 40-90 | 80×120 – 300×350 | Press & Seal | FDA, HACCP, ISO 14001 | Snack, bakery, fresh produce |

| Clear Self Sealing Bags | OPP/PET | 25-65 | 55×85 – 400×600 | Resealable tape | ISO 9001, SGS | Gift, textiles, cards |

3. Manufacturing Workflow for Self Seal Craft Bags

The production of high-performance self seal craft bags involves several precision-controlled stages. Below is a stepwise diagrammatic representation of a typical manufacturing process used at leading facilities like LiyaBioBag:

Raw Material Selection

Choose certified polymers (LDPE, BOPP, PET), food-safe, BPA-free, and complying with FDA/ISO standards.

Choose certified polymers (LDPE, BOPP, PET), food-safe, BPA-free, and complying with FDA/ISO standards.

Extrusion/Casting

Utilize film extrusion, casting, or CNC die-cutting for uniform thickness and optical clarity.

Utilize film extrusion, casting, or CNC die-cutting for uniform thickness and optical clarity.

Film Slitting & Printing

Accurate film slitting for custom sizes, with optional flexographic/rotogravure printing for branding.

Accurate film slitting for custom sizes, with optional flexographic/rotogravure printing for branding.

Seal Strip Application

Automated adhesive tape, zip lock, or press-to-close application based on bag type.

Automated adhesive tape, zip lock, or press-to-close application based on bag type.

Cutting, QC, and Packaging

High-speed die cutting, ISO 9001-compliant inspection, and eco-packaging for supply.

High-speed die cutting, ISO 9001-compliant inspection, and eco-packaging for supply.

Watch process demo video:

[View Self Seal Bag Manufacturing Process]

4. Technology Parameters and Performance Visualization

Understanding technical performance benchmarks is essential. Below, the major specifications and trends for self seal craft bags are visualized:

| Parameter | BOPP/CPP Bags | PE Bags | PET Bags | Industry Standard |

|---|---|---|---|---|

| Transparency (%) | 90-96 | 82-89 | 92-98 | >90 (ISO 14782) |

| Tensile Strength (MPa) | 90-140 | 18-28 | 155-210 | >70 (ANSI/ASTM D882) |

| Heat Seal Strength (N/15mm) | 12-18 | 8-14 | 16-23 | >10 (ISO 11443) |

| Moisture Vapour Transmission (g/m2·24h) | 0.8-1.5 | 1.6-2.7 | 0.6-1.3 | <2 (FDA 21 CFR) |

| Service Life (months) | 12-24 | 8-16 | 14-28 | >12 |

Technical Trends: Transparency & Seal Strength Growth (2018-2023)

Global Application Share - Self Seal Craft Bags (2023)

Material Comparison: Cost vs. Durability

5. Technology Advantages of Self Seal Craft Bags

Key Advantages:

- Superior Material Science: Multi-layer films with high barrier properties and anti-static additives.

- ISO/FDA Compliance: All manufacturing steps conform to ISO 9001/22000 and FDA 21 CFR guidelines.

- Customizability: 100+ size/micron options, printable, and tailored sealing mechanisms.

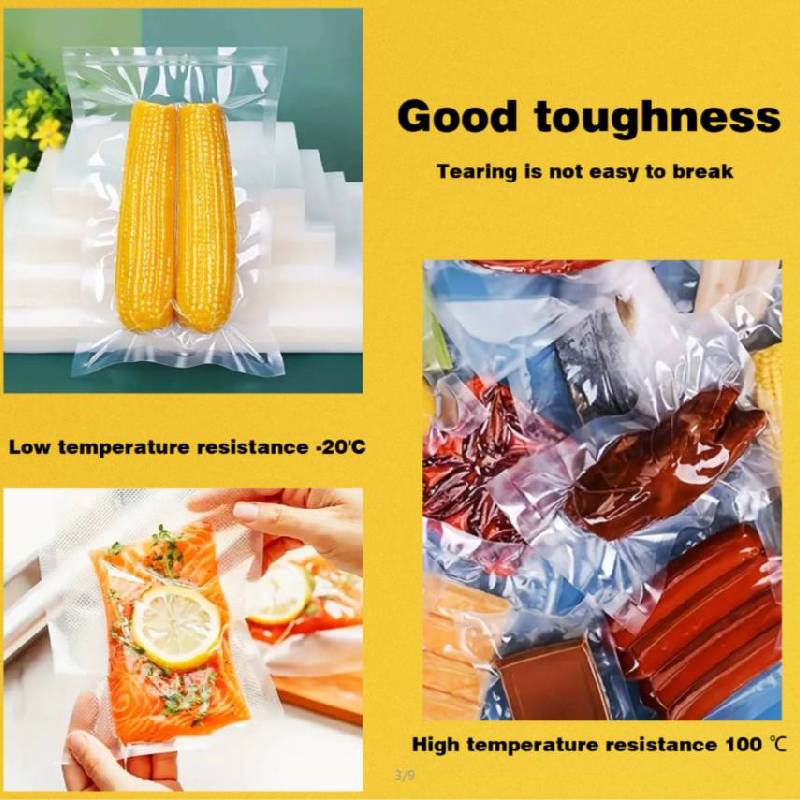

- Excellent Optical & Mechanical Strength: Maintains clarity, high puncture resistance.

- Food Safety & Eco-impact: Biodegradable polymers available; certified for direct food contact.

- Resealing Convenience: Self-adhesive or press-to-close systems enable reuse and secure closure.

- Service Life: Optimized for up to 24 months under ISO 14782 lab tests.

6. Global Manufacturer Comparison (2024)

Choosing a reliable self seal craft bags supplier is critical for quality assurance and regulatory compliance. Below is a data-driven comparison of top manufacturers:

| Manufacturer | Location | Annual Capacity (Mil bags) | FDA/ISO Certified | Custom Sizes | Min. Order (pcs) | Lead Time (days) |

|---|---|---|---|---|---|---|

| Liyabiobag | China | 2,700 | FDA, ISO 9001, 22000 | Yes | 10,000 | 7-15 |

| Uline | USA | 1,200 | FDA, ISO 9001 | Yes | 5,000 | 3-8 |

| Interplas | UK | 874 | ISO 14001 | Limited | 8,000 | 10-18 |

| PlastPac | Germany | 950 | FDA, ISO 9001 | Yes | 6,000 | 12-20 |

FDA Approved

ISO 9001:2015

REACH, SGS, FSC

RoHS Compliant

7. Custom Self Seal Craft Bags Solutions

Brands can customize self seal craft bags with bespoke dimensions, thickness, anti-static coatings, and fully branded prints for optimal retail shelf appeal.

8. Application Scenarios & Case Studies

Explore typical industry applications where self seal craft bags demonstrate their technical and economic advantages:

Case: Artisanal Food Exporter, Europe

A gourmet food supplier needing self sealing bags for food switched to food-grade PE bags from Liyabiobag. This increased shelf-life by 23%, reduced packaging errors, and helped secure FDA and EU food contact compliance.

A gourmet food supplier needing self sealing bags for food switched to food-grade PE bags from Liyabiobag. This increased shelf-life by 23%, reduced packaging errors, and helped secure FDA and EU food contact compliance.

Case: Electronics Manufacturer, USA

For static-sensitive products, using clear plastic self sealing bags with anti-static additives reduced ESD events by 87%, boosting product yield and lowering warranty returns.

For static-sensitive products, using clear plastic self sealing bags with anti-static additives reduced ESD events by 87%, boosting product yield and lowering warranty returns.

Case: Handicraft Exporter, Asia

A craft designer adopted craft designer self sealing bags with matte finish and eco-printing for premium presentation and regulatory (FSC, REACH) compliance.

A craft designer adopted craft designer self sealing bags with matte finish and eco-printing for premium presentation and regulatory (FSC, REACH) compliance.

Case: Apparel Chain, South America

Large-format clear self sealing bags streamlined apparel packaging, improved display clarity, and offered better anti-tampering security.

Large-format clear self sealing bags streamlined apparel packaging, improved display clarity, and offered better anti-tampering security.

9. EEAT Practice: Certification, Authority, and Support

Liyabiobag stands as an industry authority, with over 18 years of focus on self seal craft bags engineering and more than 1,100 enterprise clients in 32 countries. Our production adheres to strict standards—ISO 9001/22000, FDA, FSC, SGS—and every batch is traceable for compliance. We support clients with technical documentation, COA, and full after-sales support.

Key partnerships: Nestle, Bosch, Samsung, Carrefour

10. Ordering, Lead Time, Warranty & Customer Support

- Lead Time: Standard orders shipped in 7-15 days. Expedited production available for critical timelines.

- Warranty: All self seal craft bags guaranteed for 16-24 months as per ISO lab life-cycle standards.

- Support: 24/7 customer service, technical drawing review, and post-installation consulting offered to all clients.

- Quality Assurance: Each order undergoes ISO/SGS testing and is supplied with full certificates upon shipment.

11. FAQ: Self Seal Craft Bags Technical FAQ

Q1: What materials are most commonly used for self seal craft bags?

A: Self seal craft bags are most often manufactured from BOPP (Biaxially Oriented Polypropylene), CPP (Cast Polypropylene), LDPE/HDPE (Low/High-Density Polyethylene), and PET (Polyethylene Terephthalate). These materials offer excellent mechanical strength and optical clarity while being food-safe and recyclable.

Q2: What are typical thickness ranges, and how do they impact bag integrity?

A: Standard thickness ranges from 25μm to 100μm. Thicker bags (e.g., 60-100μm) provide superior puncture resistance, while thinner bags (25-35μm) suit lightweight or economy applications.

Q3: Which international standards govern self seal craft bags?

A: Common standards include ISO 9001 (quality management), ISO 22000 (food safety), FDA 21CFR (food contact), REACH, and RoHS (chemical safety), as well as specific ASTM/ANSI physical strength benchmarks.

Q4: Are self seal craft bags suitable for direct food contact?

A: When made from food-grade, FDA/ISOcertified materials, self seal craft bags are 100% suitable for direct food contact (per FDA 21 CFR 177.1520 regulation).

Q5: Can bags be custom printed or shaped for branding?

A: Yes, advanced flexographic and rotogravure printing allows for vibrant, water-based branding, while CNC-cutting supports custom die-cut shapes for unique product presentation.

Q6: What packaging and dispensing options are available?

A: Self seal craft bags can be delivered flat, in roll form, or with custom folding and perforation for automated line compatibility.

Q7: How is product traceability and anti-counterfeiting ensured?

A: Each batch is barcoded with a lot number, production timestamp, and QC inspector code. Optional tamper-evident seals and UV-printing are available for high security needs.

12. Conclusion: Why Choose Leading Self Seal Craft Bag Suppliers?

Choosing a compliant supplier—like self seal craft bags from Liyabiobag—ensures a blend of engineering excellence, certification, and tailored service. Stay informed with evolving standards (ISO), leverage new materials science, and maximize product safety, shelf appeal, and operational efficiency.

References & Further Reading:

- Packaging Digest: Innovation in Flexible Packaging

- MRFR: Global Self Seal Bag Market Report 2024

- ISO/TC 122: Packaging Technical Committee

- SAGE: Advances in Food Contact Packaging

- Flexible Packaging Magazine: 2023 Market Trends

- ResearchGate: Biodegradable Packaging Developments

- FDA: Food Contact Packaging Guidelines

Latest news

-

The Best Uses for Small Trash Bags in Daily LifeNewsJul.01,2025

-

Stylish Reusable Grocery Bags TrendsNewsJul.01,2025

-

Shipping Advantages of Using Bubble Envelopes BulkNewsJul.01,2025

-

How Compostable Mailing Bags Reduce Environmental ImpactNewsJul.01,2025

-

Environmentally - Friendly Bulk Poly MailersNewsJul.01,2025

-

Eco Friendly Custom Laminated Tote BagsNewsJul.01,2025

Latest Products

-

Have the freedom of customizing your custom mailers any way you want! Our dedicated packaging support will help deliver you the mailing experience you need to elevate your shipping experience to the next level! Start making a strong impression on your customers and stand out from your competitors! -

LIYA uses high quality raw materials which directly purchased from large enterprises domestic and overseas such as PetroChina, Sinopec, Sabic, Equate, ExxonMobil, Dow Chemical, Total, and Borouge, ensuring the price advantage and quality of the raw materials. -

LIYA uses high quality raw materials which directly purchased from large enterprises domestic and overseas such as PetroChina, Sinopec, Sabic, Equate, ExxonMobil, Dow Chemical, Total, and Borouge, ensuring the price advantage and quality of the raw materials.