Laminated Bags: Durable, Customizable Packaging for High-Impact Brands

In the world of modern packaging, laminated bags are an elite choice. They combine strength, visual appeal, and barrier protection, making them ideal for retail, food products, pet supplies, and promotional use. Whether you're sourcing laminated bags wholesale for resale or partnering with laminated bags suppliers for your brand, understanding the materials, options, and value is key to a smart purchase.

This guide covers what laminated bags are, popular use cases, customization options, and what to look for in a supplier.

What Are Laminated Bags?

Laminated bags are packaging bags made by bonding two or more layers of material—usually plastic films, paper, or foil—to create a stronger, more functional structure. Lamination improves durability, water resistance, and the ability to hold heavier or moisture-sensitive products.

Core benefits:

High barrier protection (moisture, air, odor)

Glossy or matte finish for premium branding

Strength and puncture resistance

Ideal for printing vibrant colors and photo-quality graphics

Suitable for food-grade or retail applications

They are widely used in:

Food packaging (snacks, coffee, rice, frozen food)

Cosmetics and personal care

Pet products (treats, supplements, litter)

Promotional and gift bags

Fashion and lifestyle retail packaging

Types of Laminated Bags

When choosing laminated packaging, you’ll encounter different styles and materials. The best laminated bags suppliers will offer various configurations based on your needs.

1. Stand-Up Pouches (SUP)

Most popular in food and snack industries

Bottom gusset expands when filled

Available with resealable zippers, tear notches, hang holes

2. Flat Pouches / Three-Side Seal Bags

Slim profile

Great for single-serve items, powders, or sample kits

Low-cost and space-efficient

3. Side Gusset Bags

Used for coffee, pet food, or grains

More space without sacrificing shelf footprint

Often heat-sealed and used with degassing valves

4. Box Bottom or Quad Seal Bags

Strong structure and premium look

Sits flat on shelf

High-end choice for luxury foods, supplements, or gifts

5. Laminated Shopping or Tote Bags

Made of non-woven or woven PP with laminated film

Waterproof, reusable, and brandable

Common in promotional events and retail outlets

Laminated Materials & Barrier Types

Laminated bags use combinations of:

PET / BOPP: Excellent for printing and clarity

PE / LDPE: Flexible, heat-sealable inner layer

Aluminum foil or metalized films: Superior barrier

Kraft paper + film: Eco-friendly aesthetic with strength

Woven or non-woven PP + film: Durable for tote/shopping bags

Lamination can be:

Glossy – vibrant color, sleek finish

Matte – elegant, soft-touch feel

Holographic or metallic – eye-catching display appeal

Anti-scratch or soft-touch – for high-end retail applications

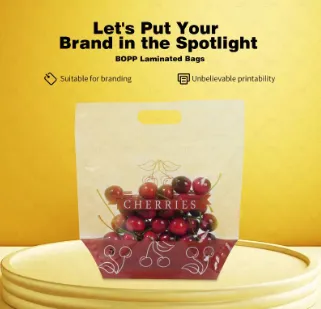

Custom Laminated Bags: Built for Your Brand

Custom laminated bags let your packaging reflect your brand with striking visuals and tailored performance. With flexible printing and multiple shapes, they’re ideal for businesses that want to stand out on the shelf.

Options include:

Full-color rotogravure or digital printing

Spot UV, embossing, or foil stamping

Custom shapes, sizes, and zipper closures

Window cutouts for product visibility

Degassing valves, spouts, and tear notches

Sustainability options (recyclable films or kraft-based laminates)

Most laminated bags suppliers require MOQs starting at 5,000–10,000 units for custom orders.

Laminated Bags Wholesale: Save Big on Bulk Orders

If you’re sourcing laminated bags wholesale, bulk purchasing allows for:

Lower unit costs (especially with factory-direct pricing)

Consistent branding across product lines

Better freight and logistics optimization

Packaging stockpiles for seasonal promotions or launches

Wholesale prices vary by bag type, lamination quality, size, and printing. Here's a snapshot:

Laminated Bags Price Guide (2025 Estimates)

|

Bag Type |

Size Example |

Price Range (USD per 1,000 units) |

|

Stand-up pouch (PET/PE) |

6" × 9" |

$150 – $300 |

|

Three-side seal pouch |

5" × 8" |

$120 – $220 |

|

Side gusset foil bag |

8" × 12" × 3" |

$250 – $400 |

|

Box bottom kraft+foil |

10" × 13" × 4" |

$350 – $600 |

|

Laminated non-woven tote |

13" × 15" × 8" |

$500 – $900 |

|

Custom full-color print |

Any type |

+$0.10–$0.50 per unit (depending on artwork) |

Choosing Laminated Bags Suppliers

When sourcing laminated bags, look for suppliers that offer:

Material expertise (food-safe, anti-static, chemical-safe options)

Custom prototyping and dieline support

Fast lead times (especially for wholesale reorders)

Packaging certifications (FDA, SGS, FSC, ISO)

Sustainable material alternatives (mono-materials, recyclable laminates)

Many laminated bags suppliers offer bundled services including branding, secondary packaging (like labels or cartons), and freight consolidation.

Laminated Bags FAQs

Q1: What is lamination in packaging?

A: Lamination involves bonding multiple layers—like plastic, foil, or paper—to create a strong, protective packaging structure with high visual impact and barrier protection.

Q2: Are laminated bags food-safe?

A: Yes—when made with food-grade inner films like PE or CPP. Always confirm with your supplier and request FDA or SGS certifications.

Q3: What’s the minimum order for custom laminated bags?

A: Most suppliers require 5,000–10,000 units per size or design. Digital print or short-run programs may allow lower MOQs.

Q4: Can laminated bags be recycled?

A: Traditional multi-layer laminates are difficult to recycle. However, recyclable or mono-material laminated options (e.g., PE/PE structures) are available from forward-thinking suppliers.

Q5: Where can I buy laminated bags wholesale?

A: www.liyabiobag.com.

-

Self Seal Bags: Secure, Clear, and Customizable Packaging for Every IndustryNewsAug.15,2025

-

Paper Cups: Bulk Solutions for Events, Cafés, and Eco-Friendly ServiceNewsAug.15,2025

-

Laminated Bags: Durable, Customizable Packaging for High-Impact BrandsNewsAug.15,2025

-

Grocery Bags: Smart, Sustainable, and Scalable Solutions for RetailersNewsAug.15,2025

-

Drawstring Bags: Versatile, Customizable, and Cost-Effective for Bulk UseNewsAug.15,2025

-

Disposable Gloves: Wholesale Solutions for Safety, Hygiene, and EfficiencyNewsAug.15,2025

-

Have the freedom of customizing your custom mailers any way you want! Our dedicated packaging support will help deliver you the mailing experience you need to elevate your shipping experience to the next level! Start making a strong impression on your customers and stand out from your competitors! -

LIYA uses high quality raw materials which directly purchased from large enterprises domestic and overseas such as PetroChina, Sinopec, Sabic, Equate, ExxonMobil, Dow Chemical, Total, and Borouge, ensuring the price advantage and quality of the raw materials. -

LIYA uses high quality raw materials which directly purchased from large enterprises domestic and overseas such as PetroChina, Sinopec, Sabic, Equate, ExxonMobil, Dow Chemical, Total, and Borouge, ensuring the price advantage and quality of the raw materials.