Self Seal Bags: Secure, Clear, and Customizable Packaging for Every Industry

When it comes to efficient and professional product packaging, few tools are as practical as the self seal bag. Whether you're shipping jewelry, storing hardware, packing pharmaceuticals, or selling apparel, self-sealing bags offer a clean, tamper-evident, and time-saving solution.

This guide covers everything you need to know—what self seal bags are, how clear self sealing bags are used across industries, what to expect from custom self sealing bags, and how to choose the right size and material for your needs.

What Is a Self Seal Bag?

A self seal bag (also called a resealable or self-adhesive bag) is a flexible plastic or poly bag with a pressure-sensitive adhesive strip at the opening. Once you fold or press the flap shut, the bag seals securely—no heat sealer, tape, or twist ties required.

Key features:

Instant seal without tools

Reclosable (for some versions) or permanent

Available in multiple materials: LDPE, BOPP, CPP

Moisture-resistant and tamper-evident

Transparent for product visibility or printed for branding

Clear Self Sealing Bags: Simple, Visible, Professional

Clear self sealing bags are widely used in retail, logistics, and manufacturing because they allow full visibility of the contents while offering protection and a clean appearance. They’re ideal when presentation and product inspection are important.

Common applications:

Apparel and garment packaging

Jewelry and craft storage

Hardware kits and parts

Instruction manuals or tech accessories

Medical and lab items

Online order fulfillment (inserts, thank you cards, return items)

Advantages of clear self sealing bags:

Fast to pack (great for high-volume shipping)

Clean and tamper-evident appearance

Protect contents from dust, moisture, and fingerprints

Lightweight for cost-effective shipping

Types of Self Seal Bags

Self seal bags come in several forms. The best option depends on your product type, sealing preference, and reusability requirements.

1. Permanent Adhesive Seal Bags

Once sealed, they can’t be reopened without tearing

Great for retail or tamper-evident packaging

Common in e-commerce fulfillment

2. Resealable Adhesive Bags

Can be opened and closed multiple times

Often used for small parts, samples, or collectables

Preferred in lab, medical, and parts packaging

3. Zipper-Lock (Press-to-Seal) Bags

Use a molded plastic track instead of adhesive

Ideal for food, pills, and frequently accessed items

4. Custom Self Sealing Bags

Printed with logo, instructions, or branding

Can include hang holes, tear notches, matte windows, or anti-static coatings

Used in fashion, cosmetics, electronics, and promotional packaging

Custom Self Sealing Bags: Add Brand, Function, and Value

If you’re using packaging as part of your customer experience or product presentation, custom self sealing bags offer big brand value. A small investment in printing or sizing gives your packaging a polished, premium feel.

Customization options include:

Full-color or spot logo printing

Matte or gloss finishes

Hang holes for retail racks

Custom flap lengths and adhesives (strong/permanent or light tack)

Die-cut windows or ventilation holes

Anti-fog or anti-static properties

Custom sizes and printing usually require a minimum order of 5,000–10,000 units, depending on material and complexity.

Choosing the Right Self Seal Bag Size

Always measure your product (especially if it’s 3D or flexible) and add space for:

A 1–2 inch flap for sealing

Clearance for folding clothing or padding around sharp corners

Width + depth = actual bag width needed

Consider a slightly larger bag if shipping labels or inserts go inside

Popular sizes include:

4" × 6" – accessories, cards, samples

6" × 9" – cosmetics, mobile accessories

9" × 12" – documents, thin clothing

10" × 13" – folded garments, catalogs

12" × 15" or larger – bulkier soft goods

Self Seal Bag Price Guide (2025 Estimates)

|

Bag Type |

Size |

Price (USD per 1,000 units) |

|

Clear resealable bag |

6" × 9" |

$20 – $40 |

|

Permanent seal mailer bag |

10" × 13" |

$45 – $70 |

|

Custom printed bag |

9" × 12" |

$80 – $150+ |

|

Anti-static or ESD bag |

8" × 10" |

$90 – $180 |

|

Resealable heavy-duty bag |

12" × 15" |

$60 – $120 |

Prices vary depending on material thickness (measured in mil or microns), printing, and closure type. Bulk orders (10,000+ units) bring significant savings.

Where to Source Self Seal Bags

You can purchase self seal bags from:

Commercial packaging suppliers

E-commerce packaging specialists

Industrial distributors (for parts or static-safe bags)

Manufacturers and OEM factories for bulk and custom orders

When choosing a supplier, look for:

Clear specs on thickness, material, and adhesive strength

Custom print support and proofing

Quick turnaround for restocks

Samples available before full production

Eco-friendly or recyclable material options if needed

Self Seal Bag FAQs

Q1: What’s the difference between resealable and self-seal bags?

A: All resealable bags are self-sealing, but not all self-seal bags are resealable. Some use permanent adhesive for tamper-proof sealing, while others allow reopening.

Q2: Are clear self sealing bags food safe?

A: Only if specified. For food applications, look for bags that are FDA-approved and made from food-grade plastic like LDPE or PP.

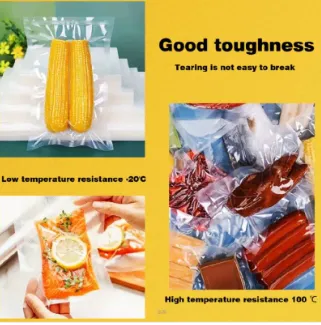

Q3: What thickness is best for self seal bags?

A: For light retail items, 1.5–2 mil is fine. For heavier or sharp products, go with 3–4 mil or reinforced film.

Q4: Can I print my logo on self seal bags?

A: Yes. Most manufacturers offer custom printed self seal bags with MOQs starting at 5,000–10,000 pieces.

Q5: Are self sealing bags recyclable?

A: Many are made from recyclable LDPE or BOPP, but always check local recycling rules and confirm material grade.

-

Self Seal Bags: Secure, Clear, and Customizable Packaging for Every IndustryNewsAug.15,2025

-

Paper Cups: Bulk Solutions for Events, Cafés, and Eco-Friendly ServiceNewsAug.15,2025

-

Laminated Bags: Durable, Customizable Packaging for High-Impact BrandsNewsAug.15,2025

-

Grocery Bags: Smart, Sustainable, and Scalable Solutions for RetailersNewsAug.15,2025

-

Drawstring Bags: Versatile, Customizable, and Cost-Effective for Bulk UseNewsAug.15,2025

-

Disposable Gloves: Wholesale Solutions for Safety, Hygiene, and EfficiencyNewsAug.15,2025

-

Have the freedom of customizing your custom mailers any way you want! Our dedicated packaging support will help deliver you the mailing experience you need to elevate your shipping experience to the next level! Start making a strong impression on your customers and stand out from your competitors! -

LIYA uses high quality raw materials which directly purchased from large enterprises domestic and overseas such as PetroChina, Sinopec, Sabic, Equate, ExxonMobil, Dow Chemical, Total, and Borouge, ensuring the price advantage and quality of the raw materials. -

LIYA uses high quality raw materials which directly purchased from large enterprises domestic and overseas such as PetroChina, Sinopec, Sabic, Equate, ExxonMobil, Dow Chemical, Total, and Borouge, ensuring the price advantage and quality of the raw materials.